Grinding machine for graphite crushing, grinding and pulverizing

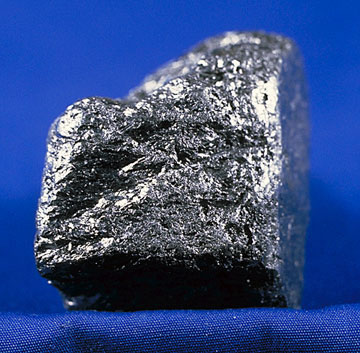

The form of carbon presence is varied: crystalline carbon, such as diamond, graphite; amorphous carbon, such as coal, etc.; carbonates, such as marble. Graphite is an allotrope of the element carbon, which in various forms widely present in the atmosphere and the earth's crust. Graphite crushing processing has now become a very important use pattern of graphite.

The form of carbon presence is varied: crystalline carbon, such as diamond, graphite; amorphous carbon, such as coal, etc.; carbonates, such as marble. Graphite is an allotrope of the element carbon, which in various forms widely present in the atmosphere and the earth's crust. Graphite crushing processing has now become a very important use pattern of graphite.Use of graphite powder:

1, Refractory materials

2, Conductive materials

3, Wear lubricating material

4, Heat exchanger

5, Casting, foundry, high temperature metallurgical materials

How to crushing and pulverizing graphite to fine and superfine powder?

Graphite grinding machine, graphite mill equipment components:

The full set of graphite mill configuration consists of hammer crusher, bucket elevator, storage silos, vibration feeder, micro powder grinding mill host, inverter classifier, double cyclone powder collector, pulse dust removal system, high pressure air, air compressor, electrical control systems.

Graphite grinding machine working principle:

When the grinding machine is working, the host motor through reducer drive spindle and turntable rotation, the turntable edge of the roll pin driven dozens of roll grinding roll grinding ring raceway.

Large materials are crushed into small particles by hammer crusher from the elevator into the storage silos, and again after vibration feeder and sloping feeding tube, the material evenly sent to the bulk material of the upper part of the dial plate.

Bulk material under the effect of centrifugal force to the periphery of, and into the grinding ring inner raceway ring rolls impact roller rolling, grinding, after the processing of the three ring road into powder, high pressure air through the suction effect of the external air sucked into the machine, and the pulverized material with a selected powder.

Impeller rotating within the classifier of the crude materials fell regrinding, in line with the requirements of the fine powder cyclone collector with the airflow into the lower part of the discharge valve discharge shall be finished by the air flow with a small amount of fine dust after pulse filter purification discharged through blower and muffler.

Features of graphite grinder machine:

1. High efficiency

Under the same finished final size and the same motor power, the capacity of HGM series vertical grinder machine is twice as much as jet mill, mixing grinder and ball mill.

2. Long life cycle of spare parts

The ring and roller are forged by special material with high utilization. Under the same grinding material and finish special size, the lifecycle of spare parts is about one year, which is 2-3times longer than impact mill or turbo mill. Furthermore, the lifetime can reach 2-5 years for grinding calcite carbonate.

3. High safety and reliability

As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

4. High fineness and flexible adjustment

The final fineness of the grinding materials can be adjusted between 325 meshes and 3000 meshes, and the product fineness can reach D97≤5um.

5. Environment-friendly

The application of pulse detuster and muffler greatly alleviates dust pollution and noise.

Model and technical data of graphite grinder machine:

| Model | HGM80 | HGM90 | HGM100 | HGM100A | HGM125 |

| Ring Diameter/mm | 800 | 930 | 1035 | 1035 | 1300 |

| Ring Number/PCS | 3 | 3-4 | 3 | 4 | 4 |

| Roller Number/PCS | 21 | 24-32 | 27 | 34-36 | 40-44 |

| Main Shaft Speed/r. p. min | 230-240 | 200-220 | 180-200 | 180-200 | 135-155 |

| Input Size/mm | ≤20 | ||||

| Finished Size/um | 5-47(325-3000) | ||||

| Capacity t/h | 0.4-4.5 | 0.4-5.5 | 0.4-6.5 | 0.4-7.5 | 0.7-10 |

| Outlet Size L*W*H/m | 13.9*4*6.2 | 14.7*4.8*7.2 | 18*4.6*8.6 | 18*4.6*8.6 | 14*9*10.25 |

| Motor Power/KW | 145-165 | 185-204 | 263 | 263-290 | 380-430 |