The purpose of the micro powder grinding mill is for super-fine grinding materials with hardness less than 6 in Moh’s scale and humidity less than 6 percent such as kaolin, limestone, calcite, marble,talcum, barite, gypsum, dolomite, bentonite mud,mica, pyrophyllite, sepiolite, diatomite, graphite, alunite, fluorite, potassium feldspar, phosphorite, pigment and so on. The granularity of the end products is 325-2500 meshes (0.044-0.0055mm).

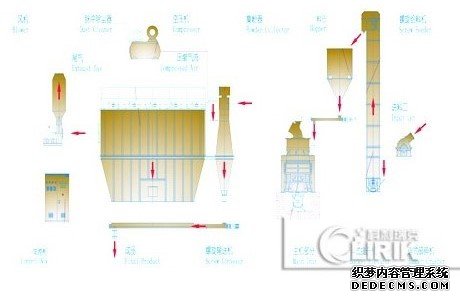

Working Principle Of Micro powder grinding mill:

The main bearing and each dial are driven by electromotor of main equipment through reducer, and numbers of rings and rolls which are rolling in the ring channels are driven by dial through plunger. After being crushed by hammer crusher, the big materials become small ones and they are sent to the storage bin by elevator. The electromagnetic vibrating feeder sends them to the middle of first dial evenly; the materials will be driven to the edge of dial by centrifugal force, and fall into the ring channels and are pressed, crushed and ground by the grinding rings and rolls. Then the materials fall into the second and third ring and crushed and ground. The high pressure centrifugal blower inhales air from the outside and blow the materials which are ground in the third ring to powder Separator. The rotating turbo in the powder Separator makes the coarse materials return to the mill and reground, while the fineness mixes with the air and be drawn to the cyclone and be discharged from the discharging valve which is in the bottom of it. The air which mixed with very little fineness are purified by impulse dust catcher and discharged by blower and muffler.

Features Of The Micro powder grinding mill:

1. High-efficiency and low consumption

With the same end-products fineness and motor power, its output is over 1 time of that of Jet Mill, Mix Mill, and Ball Mill.

2. Easy-damaged parts with longer working life

The grinding roll and ring are made of special materials. Generally, their work life is more than one year, but, which could come up to over 3 years, when it processes calcium carbonate and Calcite.

3. Security and Reliablity

Because there are no rolling bearing and bolts in the grinding chamber, we can not see the problems of bearings and sealings easily damaged and machine destroyed due to the bolts looseness.

4. Cleansing and Environment Protection

Adoption of Pulse dust collector and muffler reduces the industrial dust pollution and noise, which reaches the National Standard.

Main Specifications Of Micro powder grindng mill:

| Model | HGM80 | HGM90 | HGM100 | HGM125 | HGM168L |

| Ring Diameter(mm) | 800 | 900 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3-4 | 4 | 4 | 4 |

| Roller Number(PCS) | 18-21 | 24-29 | 28-36 | 30-44 | 30-40 |

| Main Shaft Speed (r. p. min) | 230-240 | 200-220 | 180-200 | 135-155 | 120-130 |

| Input Size (mm) | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 |

| Finished Size (um/mesh) |

74-5 (200-2500) |

74-5 (200-2500) |

74-5 (200-2500) |

100-6 (150-2000) |

100-9 (150-1500) |

| Capacity (t/h) | 0.4-4.5 | 0.6-6.5 | 1-9 | 2-16 | 3.8-30 |

| Outlet Size L*W*H (m) | 13.9*4*6.2 | 14.7*4.8*7.2 | 18*4.6*8.6 | 14*9*10.25 | 26.3*7.5*11.9 |

table 2 technical data of micro powder grinding mill:

| Unit: KW | HGM80 | HGM90 | HGM100 | HGM125 | HGM168L |

| Main Unit | 55-75 | 2*45 | 132 | 185-200 | 315 |

| Classifier | 18.5 | 18.5 | 30 | 37-4*15 | 5*18.5 |

| Blower | 45 | 55 | 75 | 2*45-2*55 | 2*75-2*90 |

| Crusher | 18.5 | 18.5 | 18.5 | 45 | 75 |

| Bucket Elevator | 3 | 3 | 4 | 4 | 7.5 |

| BeltConveyor Feeder | 2.2 | 2.2 | 2.2 | 3 | 3 |

| Spiral Conveyor | 3 | 3 | 3-4 | 2*3 | 2*5.5 |

| Discharging Valve | 2*0.75 | 1*0.75 1*1.1 | 2*1.1 | 2*1.1 | 2*0.75-2*1.5 |

| Air compressor | 11 | 15 | 22 | 2*15-37 | 55 |

Should you have any questions, please do not hesitate to contact us