Processing bauxite into powder involves several types of machinery, each designed for specific stages of the production process. Here’s an overview of the key machines used:

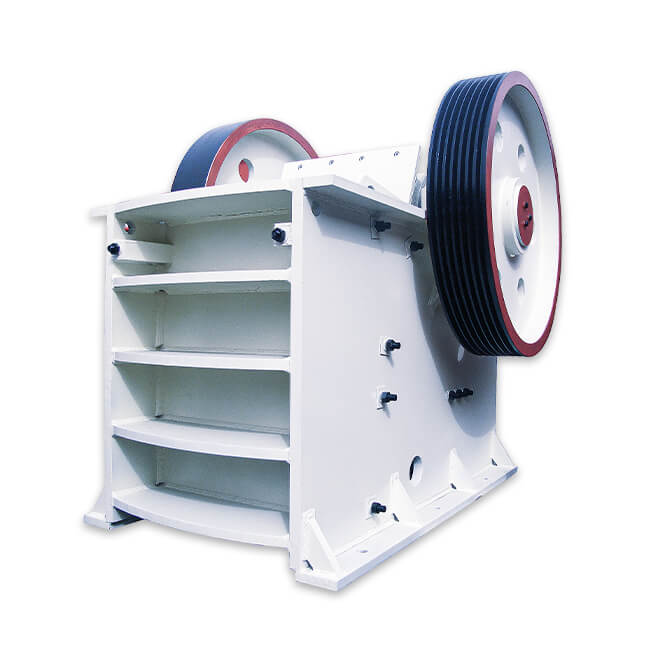

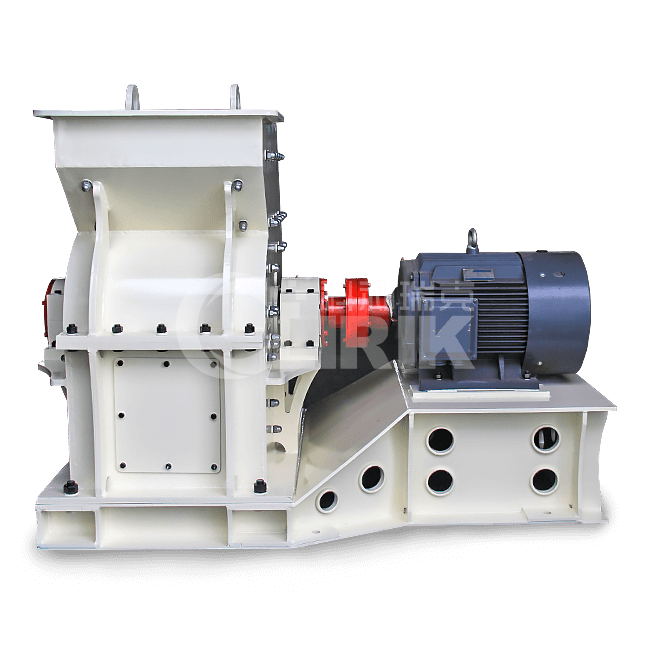

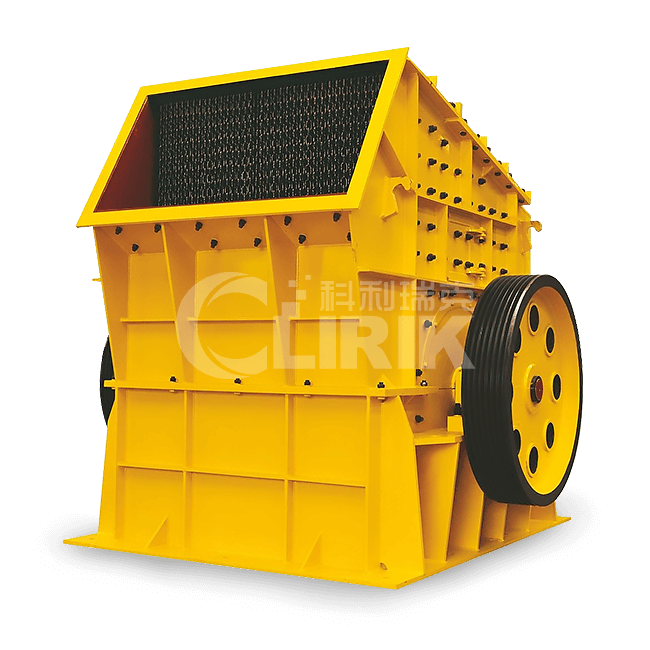

1. Crushing Equipment

(1) Jaw Crusher: Used for primary crushing of large bauxite rocks into smaller pieces, making them suitable for further processing.

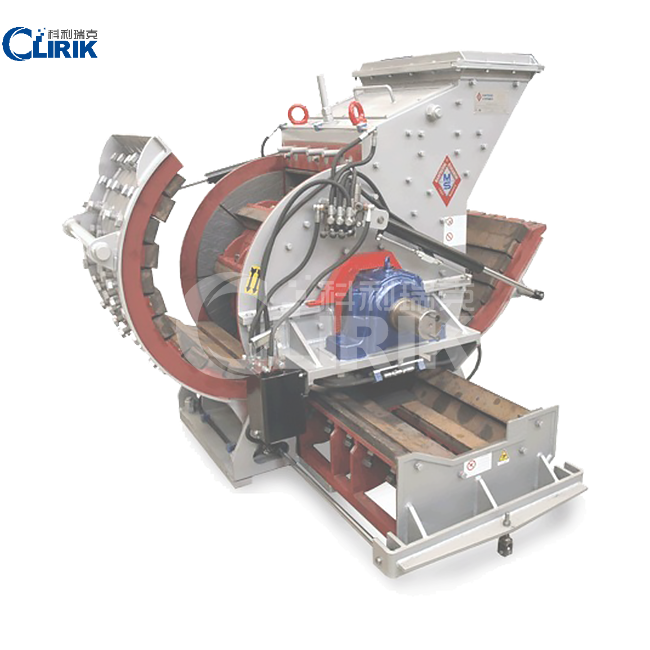

(2) Impact Crusher or Hammer Crusher: Often used for secondary crushing to achieve finer material size.

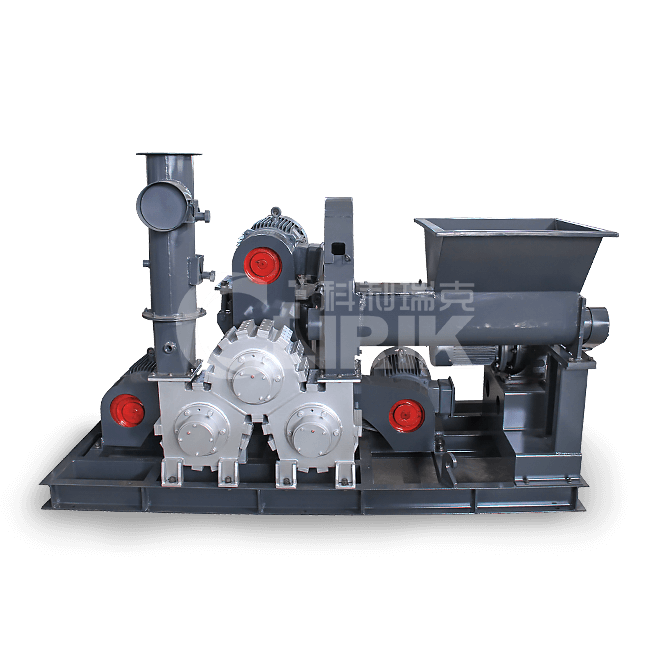

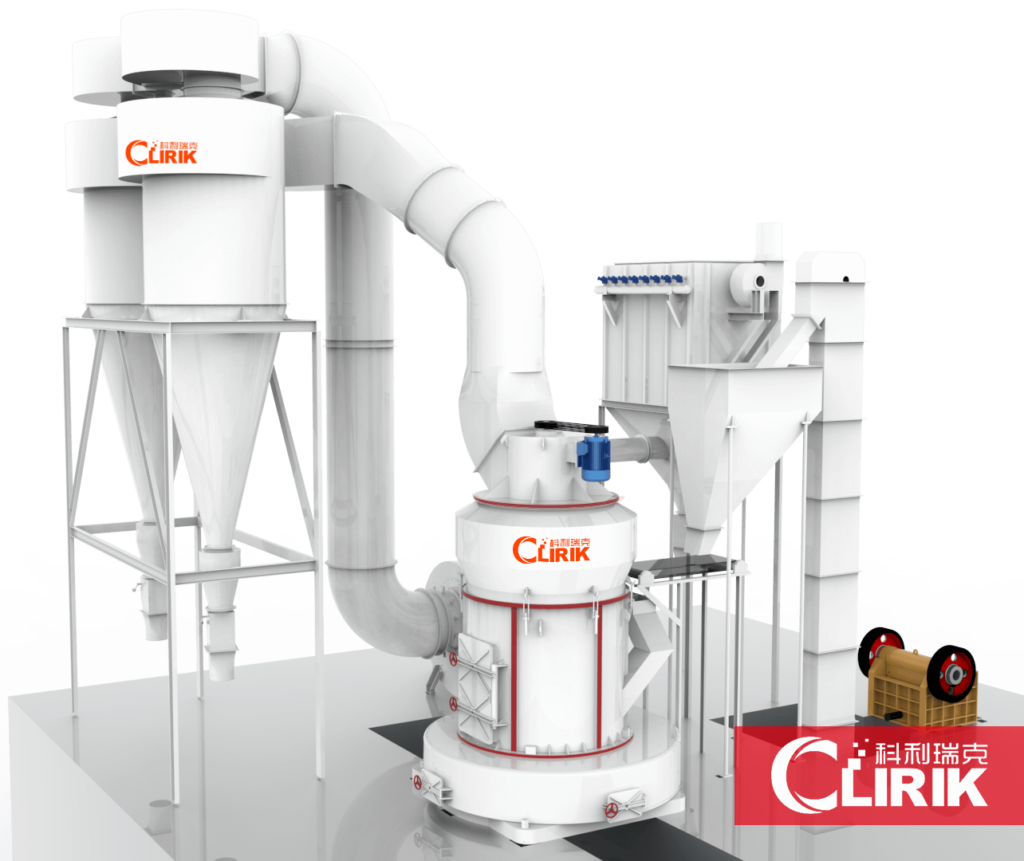

2. Grinding Equipment

(1) Bauxite powder Raymond mill : Commonly used for grinding bauxite into fine powder. It offers efficient grinding with a fine output, suitable for various industrial applications.

(2) Ball Mill: Used for finer grinding, it can produce very fine bauxite powder, especially for high-end applications.

(3) Ultrafine Mill(Bauxite vertical powder ultrafine grinding mill / Bauxite powder ultrafine grinding mill): Specialized for producing ultrafine bauxite powder (often below 10 microns), which is required in some advanced industries.

3. Classifying Equipment

(1) Classifier: Separates the finely ground bauxite powder from coarser particles. It ensures that only the desired particle size is collected as the final product.

(2) Air Separator: An alternative to classifiers, used to achieve precise powder fineness through airflow classification.

3. Drying Equipment

(1) Rotary Dryer: Removes moisture from bauxite before grinding, especially if the raw bauxite is wet. Ensures consistent grinding results and prevents clumping.

4. Feeding and Conveying Equipment

(1) Vibrating Feeder: Ensures a consistent and controlled flow of bauxite into the crushing or grinding machines.

(2) Belt Conveyor: Transports crushed or ground bauxite between different stages of the processing plant..

5. Dust Collection Systems

(1) Cyclone Collector: Collects fine bauxite powder and reduces dust in the processing environment.

(2) Bag Filter: Captures fine particles released during the grinding process, ensuring an environmentally friendly operation.

6. Storage and Packaging Equipment

(1) Silo: Used for storing the processed bauxite powder before packaging or further processing.

(2) Automatic Packaging Machine: Packs the bauxite powder into bags for easy transportation and sale.

These machines work together to process bauxite into a fine powder suitable for various industrial applications such as aluminum production, ceramics, and refractories.

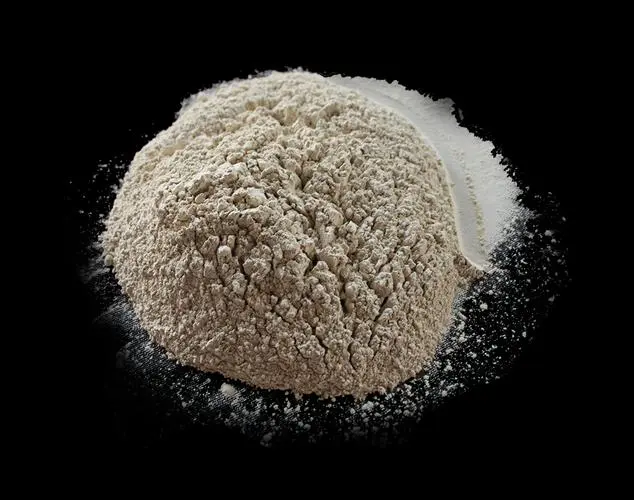

ite powder is a kind of fine powdery material obtained by crushing and grinding bauxite. Bauxite is the main raw material for refining aluminum and contains rich alumina (Al₂O₃), which is usually reddish brown or grayish-white. Bauxite powder is widely used in aluminum smelting, refractory materials, ceramics, chemical and other industries. In the aluminum production process, bauxite powder through the Bayer process or molten salt electrolysis and other processes, and finally extract pure aluminum.

Bauxite powder advantages

1. High alumina content: Bauxite powder is rich in alumina (Al₂O₃), which is an important raw material for aluminum production and has high economic value.

2. Multi-purpose: Bauxite powder is not only used in aluminum smelting, but also widely used in refractory materials, ceramics, chemical and other fields, with a variety of industrial uses.

3. High temperature resistance: Bauxite powder has good high temperature resistance, especially suitable for the manufacture of high temperature kiln refractories and casting industry.

4. Strong chemical stability: bauxite powder has good chemical stability in acid and alkali environment, and can maintain its properties under harsh industrial conditions.

5. Rich resources: bauxite resources are relatively rich in the world, the mining and processing costs are relatively low, and the supply is stable.

These advantages make bauxite powder an important raw material in many industrial production.

Crusher Equipment

Grinding equipment

Other Equipment