Table of Contents

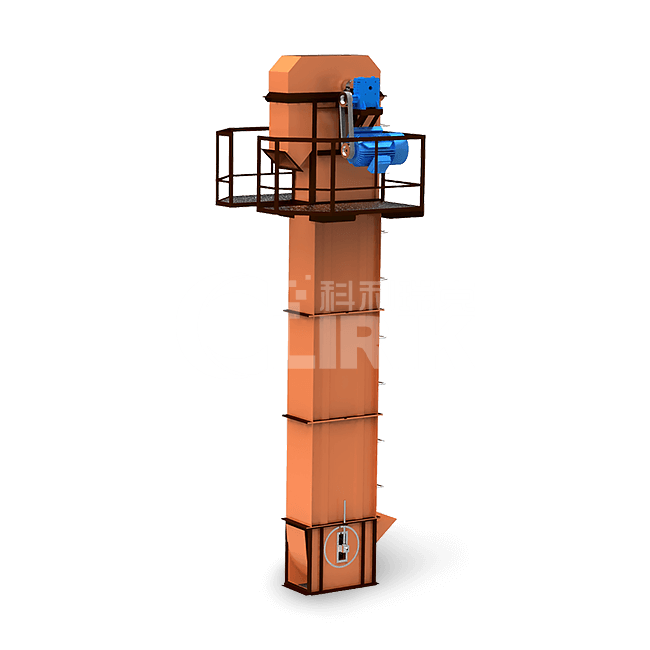

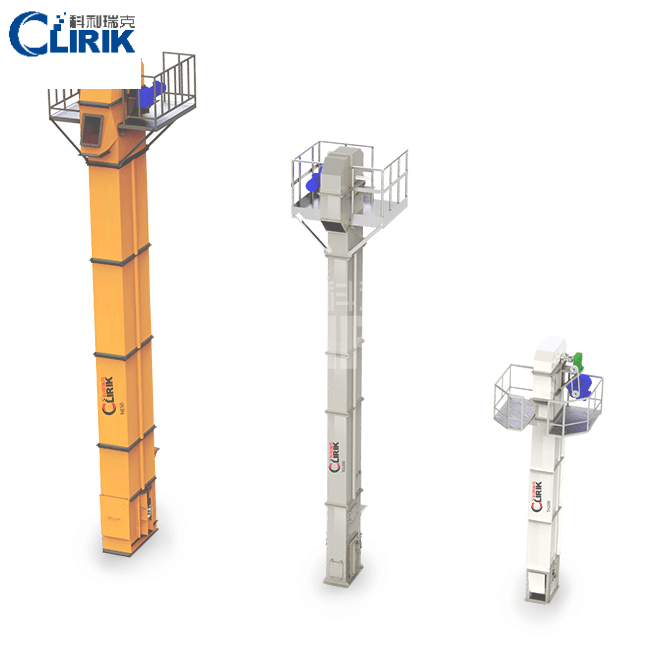

TH Series Bucket Elevator

Capacity:15.77-210 m³/h

Max feeding size: 30-60mm

Processing ability: 15.77-210 m³/h

Range of application: Ore,Coal,Cement Chamotte,Foodstuff and so on

|

Link Chain Bucket Elevator Model |

TH160 |

TH200 |

TH250 |

||||

|

Hopper Type |

ZH |

SH |

ZH |

SH |

ZH |

SH |

|

|

Capacity/(m³/h) |

15.77 |

24.97 |

17.87 |

28.6 |

31.43 |

48.19 |

|

|

Hopper |

Volume (L) |

1.2 |

1.9 |

1.5 |

2.4 |

3.0 |

4.6 |

|

|

Interval (mm) |

500 |

|||||

|

Chain |

Round Steel Diameter*Pitch(mm) |

14*50 |

|||||

|

|

Single Load(KN) |

≥190 |

|||||

|

Hopper Running Speed/(m/s) |

1.2 |

1.2 |

1.2 |

||||

|

Drive Sprocket Rotation Speed(r/min) |

69.71 |

63.22 |

44.11 |

||||

|

Conveying largest size(mm) |

20 |

25 |

30 |

||||

|

Link Chain Bucket Elevator Model |

TH315 |

TH400 |

TH500 |

TH630 |

|

|||||||

|

Hopper Type |

ZH |

SH |

ZH |

SH |

ZH |

SH |

ZH |

SH |

|

|||

|

Capacity/(m³/h) |

35 |

59 |

58 |

93 |

81 |

130 |

145 |

210 |

|

|||

|

Hopper |

Volume (L) |

3.75 |

6 |

5.9 |

9 |

9.3 |

15 |

15 |

24 |

|

||

|

Interval (mm) |

512 |

688 |

|

|||||||||

|

Chain |

Round Steel Diameter*Pitch(mm) |

φ18*64 |

φ22*86 |

|

||||||||

|

Single Load(KN) |

≥320 |

≥480 |

|

|||||||||

|

Hopper Running Speed/(m/s) |

44 |

37.6 |

39.7 |

35.8 |

||||||||

|

Conveying largest size(mm) |

35 |

40 |

50 |

60 |

||||||||

TH series bucket elevator is a commonly used lifting equipment. the series of bucket elevator adopts forged ring chain as the transmission part, has strong mechanical strength, mainly used for lifting powder and small particles and small block materials.

1. Use a series of hoppers uniformly fixedly connected to the traction member to vertically lift the continuous conveying machine of materials.

2. The amount of transmission can be adjusted according to the transmission speed, and the lifting height can be selected as needed. The hopper is designed and manufactured by our company.

3. TH Series Bucket elevator adopts inflow feeding, induced unloading, large capacity hopper intensive arrangement, so that there is little extrusion and collision between raw materials, reducing raw materials scattered;

4. Fully enclosed shell structure design, reduces dust outside.

The TH series bucket elevator consists of frame, drag part (conveyor chain), hopper, drive wheel (head wheel), feeding inlet (input inlet) and discharging outlet (output outlet).

The materials get into the bottom of the elevator through a chute. The hopper scoops up the material from the storage below, and as the conveyor belt or chain is lifted to the top, it the jacking wheel and flipped down, the TH series bucket elevator pours the material into the receiving tank. Belt drive bucket elevator transmission belt generally adopts rubber belt, mounted on or above the transmission drum and the upper and lower to the drum. Chain drive TH series bucket elevator is generally equipped with two parallel transmission chains, on or below a pair of transmission sprockets, under or above is a pair of sprockets. The TH series bucket elevator is generally equipped with casing, in order to reduce the bucket elevator dust flying.

1. High capacity. The capacity is 1 times higher than the HL bucket elevator in the same bucket width.

2. Adopt packaged sprocket, consisted of wheel body, sprocket rim which are connected by high strength bolt. It is convenient to unscrew the bolt and change sprocket rim after the sprocket wheel wear to a certain degree, which can save material, reduce the maintenance costs.

3. The heavy-duty lever tensioning device makes automatic tension be realized. Once installed, no need to adjust, and it can keep constant tension, ensure the normal operation and avoid the skid or take off the chain.

4. Stable lifting height, reliable operation, low noise, easy maintenance.

5. The conveying capacity of improved model is 30% higher than normal models.

6.The drag part is high strength low alloy steel chain whose lifetime is long. After proper heat treatment, the steel chain has very high tensile strength and wears resistance.

TH Series Bucket Elevator manufacturer Shanghai Clirik Machinery Co., Ltd is located in Pudong New Area, Shanghai, China. It is a professional enterprise specializing in research and development, production and sales of all kinds of mining equipment. The company has formed a full set of modern production lines, equipped with intelligent, standardized testing and control laboratory, with research and development, production, sales, service in one of the professional teams.

Our Advatage

1.Specialized in ultrafine powder equipment R&D and manufacturing for more than 20 years.

2.The total production area is more than 1,200,000 m², one of the biggest grinding mills manufacturers in China.

3.Our grinding mills are exported to more than 150 countries and regions in Eastern Europe, Middle East, Africa, Australia, America, etc.

4.More than 100 after-sales technicians are ready for service to you no matter what time it is.

1. What is the minimum order quantity of TH Series Bucket Elevator?

(MQQ:1set.)

2. How much is this TH Series Bucket Elevator?

(The price will be calculated according to the quantity of your order. You can leave your contact information and our sales manager will send you the detailed quotation list.)

3. Besides TH Series Bucket Elevator, do you have any other mine equipment?

(We have HGM,YGM,CLUM series ultrafine grinding mill, as well as a variety of grinding coarse powder crusher and related auxiliary equipment.)

4. What payment methods can you provide?

(T/T, L/C, D/P, D/A, Western Union, MoneyGram, Cash)