Table of Contents

SHANGHAI CLIRIK MACHINERY CO.,LTD is a pioneer enterprise, which is specialized in research,manufacture and sales of all kinds of mining equipment.

Our HGM series micro powder grinding mill、 YGM series high pressure gridning mill and CLUM series ultrafine vertical roller mill are mainly aimed at the ultra-fine milling market, They are Widely used in mining, building materials, chemical industry, metallurgy, transportation, water conservancy and other industries.which are not only renowned in domestic market but also have been sold in dozens of countries such as Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, West Asia, Australia, America, etc.,

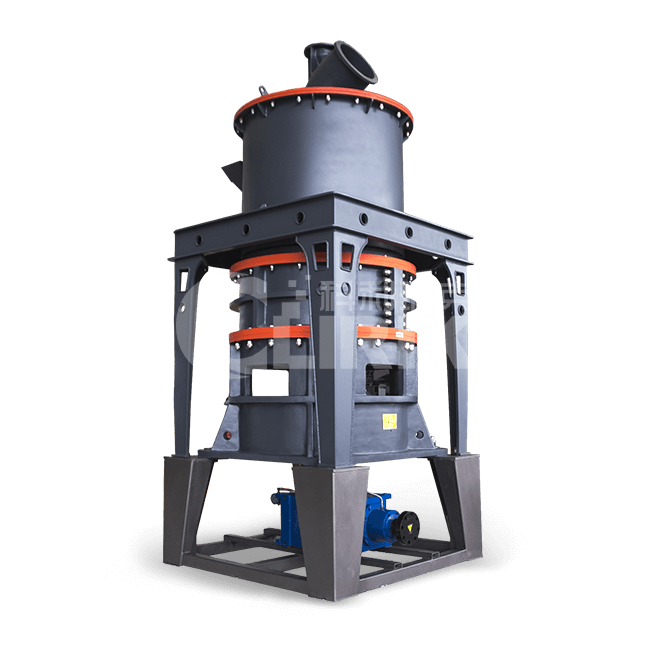

Introduction of HGM Series Micro Powder Grinding Mill

HGM Series Micro Powder Grinding Mill which we also called super fine pulverizer, because the gridning mill granularity (or final size) of the finished products can be freely adjusted between 325-3000meshes (0.045-0.0057mm) .

Finished Size: 150-2500 mesh

Processing Ability: 1-45 t/h

Max Feeding Size: 10-25 mm

Range of application:

Calcite, Chalk, Calcium carbonte, Limestone, Colomite, Kaolin, Bentonite, Talc, Mica, Magnesite, Illite etc.

Benefit:

1.The yield is 40% higher than other mills.

2.High utilization rate of Wear material:2-5years.

3.Adjustable particle size:325-3000mesh.

4.High safety and reliability. The design of the mill is rigorous, so no screw loosening to damage the machine.

5.Closed system, so it is the green and ideal equipment for environment protection.

Parameter of HGM Series Micro Powder Grinding Mill

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

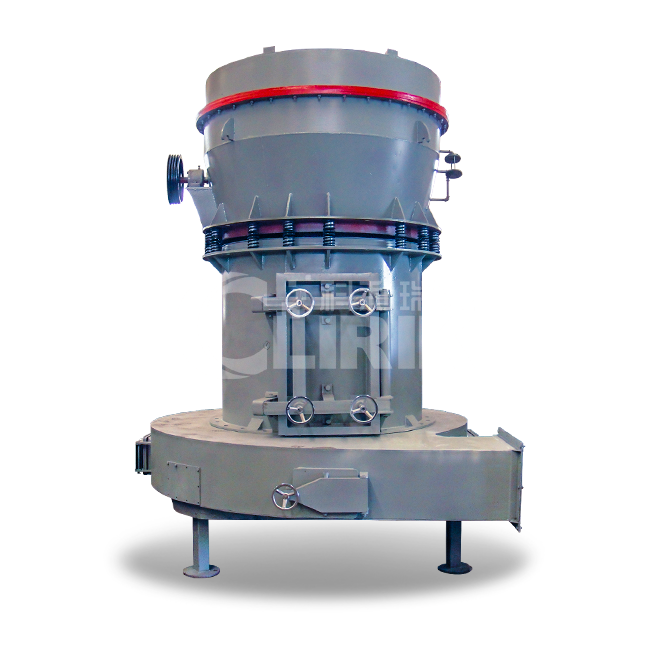

Introduction of YGM Series High Pressure Suspension Grinding Mill

Finished Size : 50-325 mesh

Processing Ability: 1-30t/h

Max feeding Size: 20 mm

Range of application:

Chalk, Calcium carbonte, Limestone, Colomite, Kaolin, Barite, Gypsum, Alunite, Graphite, Fluorite, Bentonite, Talc, Mica, Magnesite, Illite etc.

Benefit:

1.Smooth vibration damping design to reduce noise

2.Convenient blade adjustment design, can freely adjust the fineness of finished materials

3.High-pressure spring design, improve output, improve pass rate, pass rate up to D97

4.The machine has strong material applicability and is suitable for a variety of materials with Moh hardness less than 6

5.Grinding device adopts superimposed sealing, good sealing performance

Parameter of YGM Series High Pressure Suspension Grinding Mill

| Model | Roller | Ring | Feeding Size(mm) |

Finished Size(mm) |

Mill System Power(KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

| Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1.0-3.0 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12.0 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16.0 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8.0-20.0 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28.0 | 11550*9500*1050 |

Introduction of CLUM Series Ultrafine Vertical Roller Mill

Finished Size : 600~3000 meshes

Processing Ability : 3 -15t/h

Max feeding Size : 10 mm

Range of application:

Calcium carbonte, Limestone, Colomite, Kaolin, Barite, Gypsum, Alunite, Graphite, Fluorite, Bentonite, Talc, Mica, Magnesite, Illite etc.

Benefit:

1.High grinding efficiency: save 20~30% power consumption compared with the ball mill.

2.Strong drying capacity: dry and grind raw materials with moisture content as much as 15%.

3. Mutifunction: crushing, drying, grinding, separating and conveying.

4. Low noises and little dust: no direct contact between the grinding rollers and grinding disc, so metallic impact is avoided and its noises is 20~25 decibels lower. Totally closed negative pressure operation has employed by this vertical grinding mill, so there is little dust during the operation.

5. Low wear rate and little metallic pollution: its metal wear is only 5~10g/t.

Parameter of CLUM Series Ultrafine Vertical Roller Mill

| Main Configuration and Production | |||

| Model Item | CLUM1425 | CLUM1632 | CLUM1736 |

| Working Diameters(mm) | 1400 | 1600 | 1700 |

| Number of rollers(pieces) | 3 | 3 | 3 |

| Number of classifier(pieces) | 5 | 7 | 7 |

| Power of classifier(Kw) | 5X15 | 7X15 | 7X(15~18.5) |

| Main unit power (Kw) | 250 | 315 | 355 |

| Blower power(Kw) | 200 | 250 | 315 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

| Less than 2μm=34% output(t/h) |

11-14 | 13-17 | 15-19 |

| Less than 2μm=46% output(t/h) |

7-8 | 9-10 | 11-12 |

| Less than 2μm=60% output(t/h) |

3-4 | / | / |

| Material: based on calcite Particle size distribution: measured by micro laser diffraction particle size analyzer in British Malvern3000 instruments |

|||

— SHANGHAI CLIRIK MACHINERY CO., LTD

Our company already has a complete modern production line, equipped with intelligent and standardized testing and control laboratories, and has a professional team integrating R&D, production, sales and service.

Pre-sale service:

1.Clirik provides a variety of mining equipment for you to choose from.

2.Clirik will recommend suitable production lines and grinding equipment to you according to your site.

3. Clirik customizes the logo and color of the grinding equipment according to your company image.

4. Clirik provides third party inspection to ensure the quality of your grinding equipment.

After-sales service:

1. Clirik provides you with online installation and use videos.

2. Clirik will provide you with technicians to install and debug the grinding equipment.

3. Clirik trains you the technicians who use and maintain the grinding equipment.

4. Clirik provides you with a one-year warranty and lifetime service for the grinding equipment.

Certification