Table of Contents

PEX Jaw Crusher

Output Size: 25-105 mm

Feed size.: <250 mm

Capacity: 1-90 t/h

MQQ : 1 set

Price: 2000 – 30000 $

Use Range : Calcite、Calcium Carbonate、Dolomite、Gypsum、Carbon Black、Gypsum、Kaolin、 Marble …

Application : Mining、Chemiscal、 Pigment、 Plastic、Transport and many other different areas.

| Model | PEX-150 × 250 | PEX-150 × 750 | PEX-250 × 750 | PEX-250 × 1000 | PEX-250 × 1200 | PEX-300 × 1300 |

| Opening Size(mm) | 250 × 150 | 750 × 150 | 750 × 250 | 1000 × 250 | 1200 × 250 | 1300 × 300 |

| Feed Size(mm) | 125 | 125 | 210 | 210 | 210 | 250 |

| Output Open Range(mm) | 10-40 | 18-18 | 25-60 | 25-60 | 25-60 | 25-105 |

| Power(KW) | 5.5 | 15 | 22-30 | 30-37 | 37 | 75 |

| Capacity(t/h) | 1-5 | 5-16 | 15-30 | 16-50 | 20-60 | 20-90 |

| Size(mm) | 875 × 758 × 850 | 1200 × 1500 × 1200 | 1667 × 1545 × 1020 | 1530 × 1992 × 1380 | 1900 × 2192 × 1430 | 2720 × 1950 × 1600 |

| Weight(t) | 0.81 | 3.8 | 5/td> | 7 | 8 | 11 |

The PEX Jaw Crusher consists of two jaw plates, a movable jaw, and a static jaw, forming a crushing chamber, which simulates the movement of the two jaws of an animal to complete the material crushing operation. It is widely used in stone mining, metallurgy industry, building material, highway, railway, water conservancy, and chemical industries. Various materials with compression resistance less than 320MPa can be crushed.

1 High crushing ratio, uniform particle size.

2 Point eclipse discharge opening adjustment devices, reliable and easy to adjust the range to meet the needs of different customers.

3 Safe and reliable lubrication system, easy to replace parts, low maintenance workload.

4 Simple structure, reliable function, low operating cost.

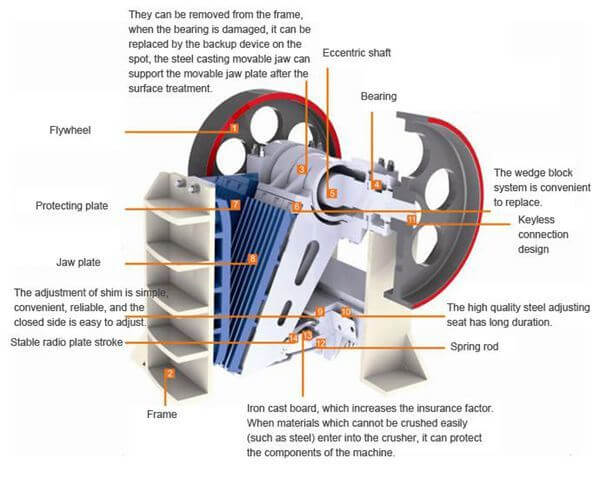

Working Principle

The working mode of PEX jaw crusher is mobile and extrusion. The working principle is as follows: The jaw crusher uses the motor as the powder. The eccentric shaft is driven by the wheels of the motor, the V-belt, and the grooved wheel so that the movable jaw plate moves according to the prescribed orbit.

Therefore, the material in the crushing cavity which is composed of the fixed jaw plate, movable jaw plate, and the side backplate, can be crushed and discharged through the discharge port.

When the jaw crusher is working, the movable jaw plate cyclically reciprocates against the fixed jaw plate, sometimes approaching and sometimes leaving.

When approaching, the material is crushed by squeezing, splitting, and impact between the two jaws; when leaving, the crushed material is discharged from the discharge port by gravity.

CLIRIK is an excellent manufacturer of mining ore machinery, crushers, and pulverizers in China, and a leader in ore ultrafine grinding machinery. Always adhere to “quality-oriented, customer first”. Over the years, based on our own technology and experience, we have continuously researched, developed, and improved ore crushers and ore mills. Strive to create cost-effective and high-quality machinery, improve customer experience, and bring customers higher benefits.

1. One year guarantee for whole machine except for wear parts.

2. 24 hours technical support by email.

3. Calling service.

4.User manual available.

5. Reminding for the service life of the wearing parts.

6. Installation guide for clients from both China and abroad.

7. Maintance and replacement service.

8. Whole process trainling and guidance from our technicians.

Q: Are you a middle man or manufacturer?

A: Our Shanghai Clirik Machinery is a professional mining equipment manufacturer.

Q: How to get in touch with you?

A: You can leave your inquiry below this product, or you can call us +86 135 1213 7665

Q: Where is your company?

A: We are in PuDong new area, HeQing twon, FuQing road, No. 19, Shanghai, China.