Table of Contents

PC series European coarse powder grinding mill is engaging in crushing various rocks and stones(such as Limestone, calcite, barite, dolomite, potassium feldspar, marble, talcum, gypsum, kaolin, bentonite, medical stone, rock phosphate, manganese ore, quartz, active carbon,glass ect) with comprehensive strength not higher than 320 MPa into coarse powder and small particles, it is widely used in metallurgy, mining, chemical, cement, coal, sand-making, coal gangue, construction, refractory materials and ceramic industries.

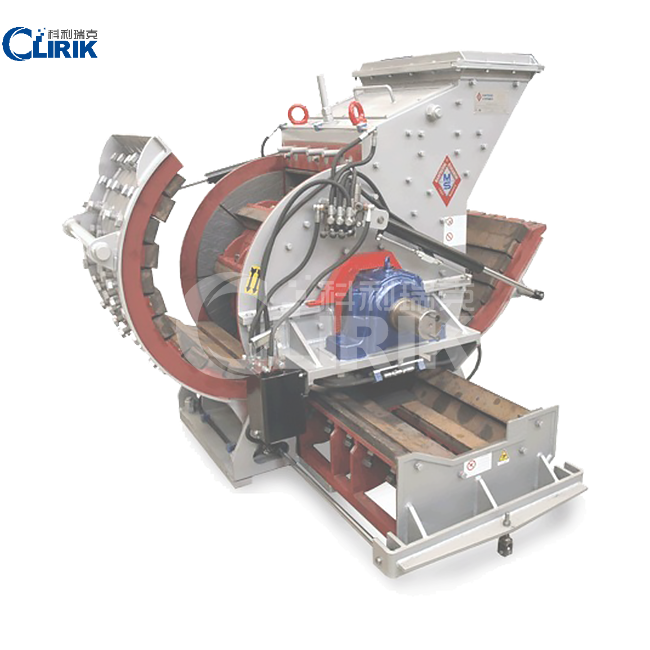

PC series European coarse powder grinding mill

Finished Size: 80-300 mesh

Max feeding size: 80mm

Processing ability: 10-100t/h

MQQ: 1 Set

Price: 999-29999 $

Range of application: Barite, quartz, feldspar, mica, calcite, talc, apatite, gypsum, fluorite, limestone, dolomite, diatomite, ceramic soil, clay, marble, granite, fly ash, kaolin, calcium carbonate, slag, bauxite, glass, etc.

Before starting, the oil temperature in the mill must be preheated to 15℃ ~ 30℃, not more than 30℃.

1. Check before startup.

Check whether all access doors are tightly closed, check whether bolts are loose, and ensure that all lubrication points are fully lubricated according to the lubrication system table and lubrication position chart.

2. Startup sequence.

Start the analytical machine after the material is stored in the bin.

(1) Start the centrifugal fan (start with empty load and load again after normal operation).

(2) Start the host, in the complete start of the host can start electromagnetic vibration feeder. At this point, the grinding work begins.

(3) The startup operation sequence is simply expressed as follows: Analysis machine → centrifugal fan → host machine → electromagnetic vibration feeder.

1. The European coarse powder grinding mill shutdown precondition.

The operation of the equipment can be stopped only after all the materials on the equipment are processed and exported.

2. European coarse powder grinding mill stop sequence.

When stopping, shut down the equipment in the forward direction of the production process, which is opposite to the starting sequence. The recommended stopping sequence is as follows:

(1) Turn off the electromagnetic vibration feeder and stop feeding.

(2) Stop the host after about one minute.

(3) Stop the centrifugal fan after blowing the residual powder.

(4) Shut down the analytical engine.

The shutdown sequence is: Electromagnetic vibration feeder → main engine → centrifugal fan → analysis machine.

The mill If any part of the PC series European coarse powder grinding mill has abnormal noise, or the load suddenly increases, it should be stopped immediately for inspection and troubleshooting. If there is more material in the European coarse grinding mill, some material must be removed from the mill before starting the mill again. Otherwise, the starting current will be too large when starting the mill again, which will cause start-up difficulties and even burn the motor.

PC series European coarse powder grinding mill maintenance is an important link to extend its service life.

1.Clean the equipment and keep the workbench clean and tidy.

2. Often pay attention to the fasteners’ fixed and tightness.

3. Check the condition of the sieve strip for coarse European powder. If there is any blockage, it should be removed immediately.

4. Pay attention to check the wear degree of easily worn parts and replace the worn parts at any time.

5. The feeding should be uniform, to prevent the occurrence of super negative phenomenon.

6.It is strictly prohibited to put materials that can not be broken into the hammer crusher.

7. It is strictly prohibited to make any adjustment, cleaning and maintenance when the machine is running, so as to avoid danger.

8. If a fault occurs when the machine is working, it should be stopped immediately for repair before it can continue to work.

9. When stopping, all materials in the machine must be spit out, and the power supply must be cut off first during maintenance.

10. PC series European coarse powder grinding mill bearing refueling should be timely, three months to replace the lubricating oil once, oil change must use clean gasoline or kerosene carefully clean the bearing.