Table of Contents

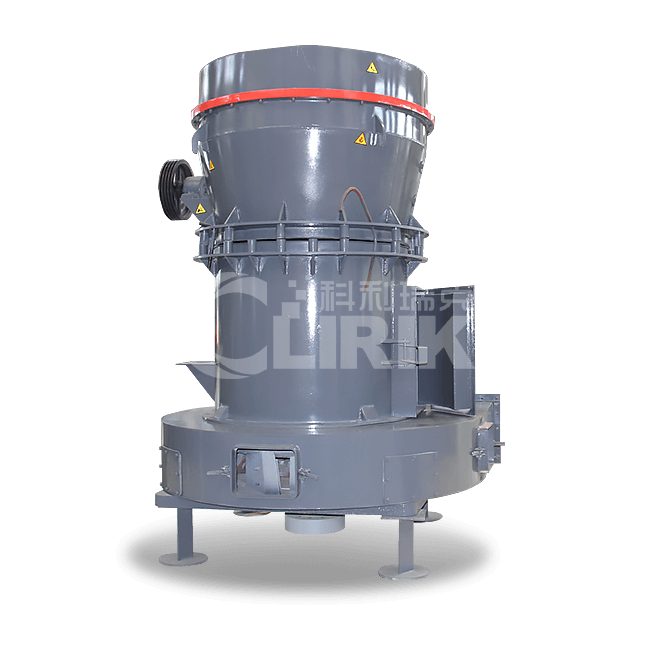

Finished Size : 50-325 mesh

Power: 18.5-132 kw

Processing Ability: 1-30t/h

Max feeding Size: 20 mm

Range of application: Calcium Carbonate 、Limestone 、Kaolin、Gypsum 、Bentonite、Dolomite…

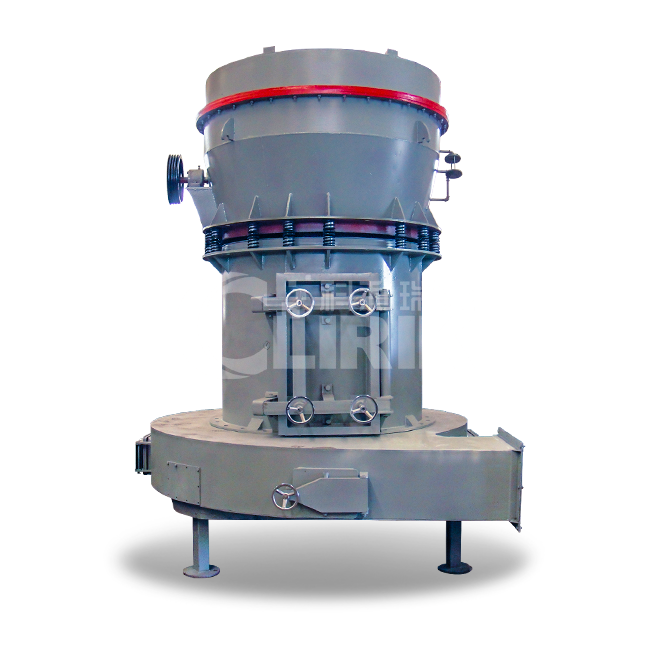

This Thailand customer plans to produce 300 mesh limestone, The client’s budget is limited, so we recommended the Limestone powder pulverizer (High Pressure Suspension Grinding Mill ) for him.

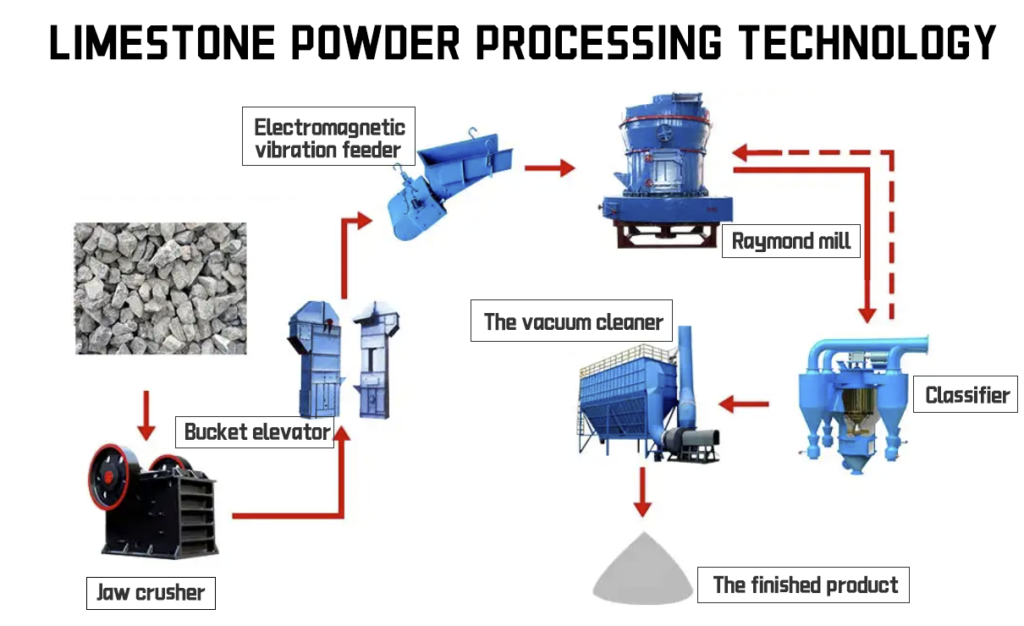

Limestone Pulverizer (High Pressure Suspension Grinding Mill) has low investment cost and can automatically adjust fineness according to the needs of 50-325 mesh, which helps customers to produce a variety of fineness limestone powder in the later stage and seek a broader application market. The following is the limestone powder production line scheme we designed for him:

Limestone powder is mainly used in the following ways:

1. Compared with the jet mill, the High Pressure Suspension Grinding Mill has a wider application range.

2. Compared with other similar mills, the grinding force of the grinding roller on the material is increased by 800-1200 Kg under the action of the high-pressure spring.

3. Energy saving. With the same output and fineness, the system energy consumption is only one third of that of jet mill.

4. Small investment and high return. In the case of the same output and fineness, the price of high-pressure micro-powder mill is only one-eighth of that of jet mill.

5. The grinding device adopts overlapping multi-stage sealing, which has good sealing performance, no dust and noise problems during operation, and is more low-carbon and environmentally friendly.

6. The degree of automation is relatively high, the operation is easy, the parts are easy to disassemble, and the maintenance is convenient.

The working principle of the high pressure grinding mill is similar to that of the traditional Raymond mill, but the grinding device is equipped with a high pressure spring with a pressure of 1000-1500kg. When the machine is working, the grinding roller of the high-pressure roller mill rotates around the main shaft, and rolls close to the grinding ring under the action of the high-pressure spring and centrifugal force, and its rolling pressure is 1.2 times higher than that of the Raymond pulverizer under the same power conditions, so The output of the high pressure pulverizer is greatly improved.

When the material to be ground enters the grinding chamber, it is scooped up by the shovel and sent to the grinding roller and the grinding ring for rolling. The crushed powder is brought into the analyzer with the circulating air of the blower. Qualified fine powder enters the cyclone powder collector with the airflow. Larger particles fall back into the grinding chamber for regrinding. The circulating air returns to the blower to repeat the above process, and the remaining air enters the bag filter for purification. After the grinding roller and the grinding ring reach a certain level of wear, adjust the length of the high pressure spring to maintain a constant grinding pressure between the grinding roller and the grinding ring. So as to ensure stable output and fineness.

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a professional enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment.

CE, ISO9001

Factory sell directly

30 years experience, professional

Sales market all over the world

Accepted delivery terms: FOB, CFR, CIF, EXW, CPT, DDU, express;

Acceptable payment currency: USD;

Acceptable payment methods: T/T, L/C, Western Union;