Table of Contents

The above video is the video of our company’s HGM series ultrafine powder grinding mill sent to Pakistan.

The HGM80 ultrafine powder grinding mill purchased by the customer is used to process 400-2000 mesh marble powder, and the output is adjusted to 0.5-5 tons per hour according to the fineness.

After many comparisons, the Pakistani customer chose our HGM series ultrafine powder grinding mill, mainly because of the many outstanding advantages of this grinding machine:

1. High efficiency and energy saving.

In the case of the same finished product fineness and motor power, the output is more than 1 times higher than that of jet mill, stirring mill and ball mill.

2. Long service life of wearing parts.

Grinding rollers and grinding rings are forged from special materials, which greatly improves the degree of utilization.

In the case of the same material and finished product fineness, the service life of the wearing parts is 2-5 times longer than that of impact crusher and turbo pulverizer, generally up to more than 1 year. When processing calcium carbonate and calcite, the service life can reach 2-5 years.

3. High safety and reliability.

There are no rolling bearings and no screws in the grinding chamber, so there is no problem of easy damage of bearings and seals, and no problem of easy loosening of screws and damage to the machine.

4. High product fineness.

The product fineness can reach D97≤5um at one time.

5. Environmentally friendly and clean.

The pulse dust collector is used to capture dust, and the muffler is used to reduce noise, which has the characteristics of environmental protection and cleanliness.

HGM series ultrafine powder grinding mill is independently developed and produced by our company. It is a professional industrial mineral equipment for grinding non-metallic ore 150-3000 mesh ultra-fine powder.

There are 5 models of this ultra-fine powder grinding mill. Customers can choose the most suitable model according to actual production needs. The model parameters are as follows:

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

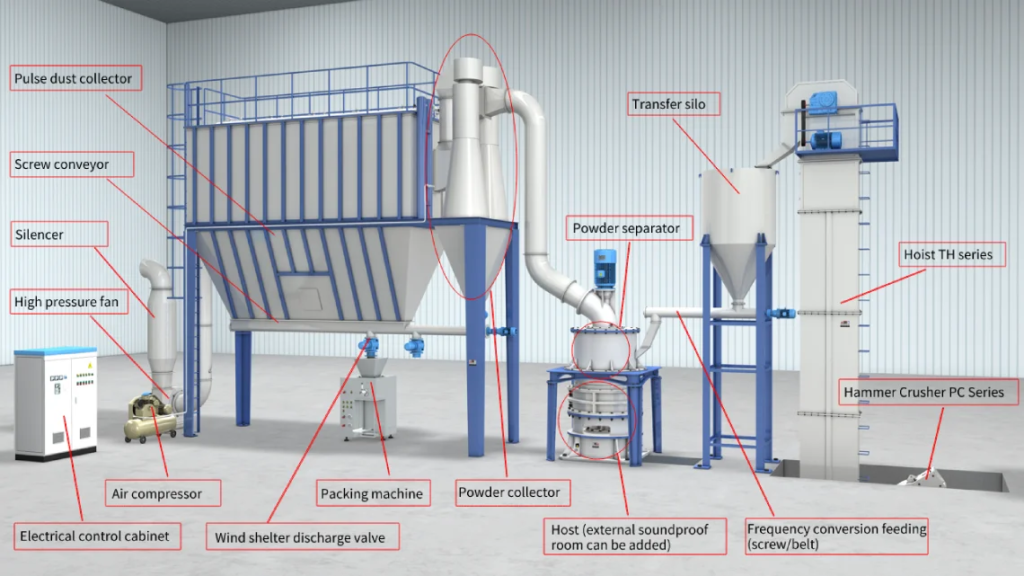

In addition to the ultrafine powder grinding mill equipment, we can also provide customers with the planning of the entire grinding production line, including crushing links (coarse crushing: jaw crusher, medium and fine crushing: cone crusher, hammer crusher, etc.), conveying links, grinding link, powder collecting link, etc. The whole production line is as follows:

● Adapt measures to local conditions, plan optimization

The production line construction plan is designed by our professional team based on the data of the field examination room and the customer’s production needs, and the production and operation process is smooth.

● Small footprint

The ultra-fine ring roller mill occupies a small area, which saves industrial land area, reduces the total cost of project investment, and improves customer benefits.

● Highly automated, good comprehensive benefits

The whole production line is highly automated, with high grinding efficiency, more stable operation, reduced maintenance intensity and production costs, high-quality finished products, and good comprehensive benefits.

If you need to purchase ore grinding equipment, please feel free to contact us! In addition to HGM series ultra-fine mills, we also have CLUM series ultrafine vertical roller mill, YGM series high pressure suspension grinding mill, CLRM series enhanced roller grinding mill, and other series of coarse powder mills.