Table of Contents

Finished Size: 150-2500 mesh

Processing Ability: 1-45 t/h

Max Feeding Size: 10-25 mm

MQQ : 1 Set

Price: 59999- 159999 $

Range Of Application: Calcium Carbonate 、Limestone 、Kaolin、Gypsum 、Bentonite、Dolomite…

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

HGM Series Ultrafine powder grinding mill specialized in producing fine and superfine powder of non-inflammable non-explosive and brittle materials with Moh’s hardness under six, such as calcite, chalk, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, illite, pyrophyllite, and vermiculite, sepiolite, attapulgite, rectorite, diatomite, barite, gypsum, alunite, graphite, fluorite, rock phosphate, kalium ore, pumice, fly ash, etc., totally more than 100 kinds of materials.

With the same final particle size of the finished product, the capacity of ultrafine powder grinding mill is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30%.

The ring and roller are forged by special material with high utilization. Under the same grinding material and finish a special size. The lifecycle of spare parts is about one year, which is 2-3 times longer than an impact mill or turbo mill. Furthermore, the lifetime can reach 2-5 years for grinding calcite carbonate. The lifestyle of spare parts is variable for the material’s hardness.

As there are no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

The final fineness of the grinding materials can be adjusted between 200 meshes and 2500 mesh (74-5micron).

The application of pulse bag filter and muffler greatly alleviates dust pollution and noise.

Let the material feed into the machine evenly, adjust the main speed to fit for grinded material, the fineness more stable. So as to increase the capacity and efficiency, reduce the powder consumption.

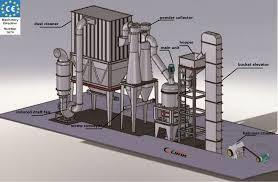

Working Principle of ultrafine powder grinding mill

1. The crusher will crush the big materials into small ones, and then the elevator will send them to the hopper.

2. The vibrating feeder will send the materials to the middle of first dial evenly.

3. The motor of main equipment drives the main shaft and dial through reducer, and the dial drives numbers of rollers moving in the ring channels via pins.

4. The materials will be driven to the edge of dial by centrifugal force and fall down into the ring, crushed and grinded by roller, and become powder after production of three rings.

5. The high pressure centrifugal blower will inhale air from outside and bring the crushed materials to classifier.

6. The rotating turbo in the powder collector will make the coarse materials return to the mill and regrounded, while the fineness will mix with the air and go into the cyclone and be discharged in the discharge bin, which is at the bottom of it.

7. The air, which mixed with very little fineness, will be purified by impulse duster and discharged by blower and muffler.

The following picture is the marble powder machine site of our previous customers.

If you want more information, you can click here to contact our customer service staff.

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai China as a professional enterprise, which specializes in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production lines, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

Pre-sale service:

1. Clirik provides a variety of mining equipment for you to choose from.

2. Clirik will recommend suitable production lines and grinding equipment to you according to your site.

3. Clirik customizes the logo and color of the grinding equipment according to your company image.

4. Clirik provides third party inspection to ensure the quality of your grinding equipment.

After-sales service:

1. Clirik provides you with online installation and uses videos.

2. Clirik will provide you with technicians to install and debug the grinding equipment.

3. Clirik trains you the technicians who use and maintain the grinding equipment.

4. Clirik provides you with a one-year warranty and lifetime service for grinding equipment.