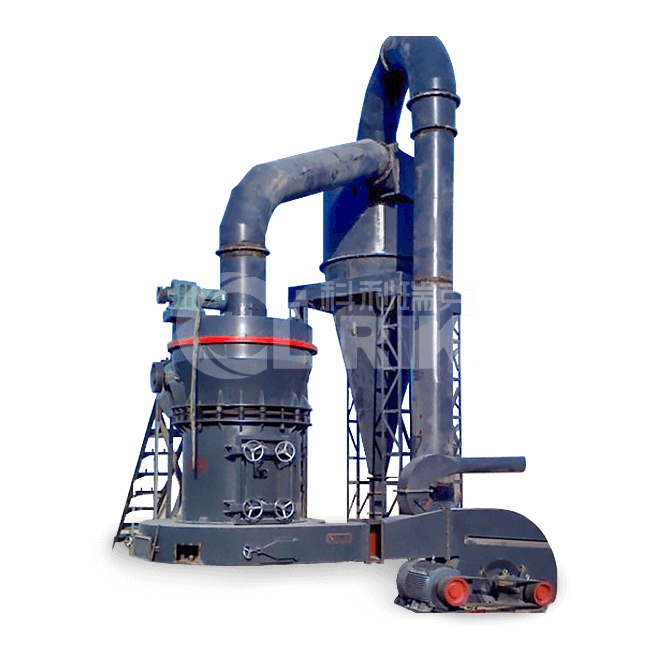

Fluorite powder high pressure suspension grinding mill is a type of grinding mill that uses high pressure springs to increase the pressure on the grinding roller and grinding ring, thus increasing the output and fineness of materials.

It is commonly used in the processing of non-metallic minerals such as fluorite, barite, talc, gypsum, and limestone.

The working principle of the high pressure suspension grinding mill is that the grinding roller is pressed tightly against the grinding ring by the action of the high-pressure spring.

The material to be ground is fed into the grinding chamber through the feeding device, and is ground between the grinding roller and the grinding ring under the action of centrifugal force.

The high pressure suspension grinding mill has the advantages of high efficiency, low energy consumption, and low noise. It also has a wide range of applications in industries such as mining, metallurgy, chemical engineering, building materials, and construction.

When using the high pressure suspension grinding mill for fluorite powder processing, it is important to pay attention to the selection of suitable grinding parameters such as the feeding size, moisture content, and hardness of the material.

It is also necessary to regularly maintain and replace the grinding roller and grinding ring to ensure the normal operation and longevity of the equipment.

Fluorite powder is a fine powder made from fluorite, a mineral composed of calcium fluoride (CaF2). It is usually produced by grinding fluorite ore or concentrate to a fine powder.

Fluorite powder is widely used in various industries such as metallurgy, chemical engineering, ceramics, and glass making. It has several important properties that make it useful in these applications, including:

Fluorescence: Fluorite is known for its unique fluorescence properties. When exposed to ultraviolet light, some fluorite powders can emit a bright glow.

Optical properties: Fluorite has a high refractive index, making it useful in the manufacture of lenses and other optical components.

Chemical properties: Fluorite is chemically stable and has low reactivity with other substances, making it useful in chemical processing and as a flux in metallurgy.

Thermal properties: Fluorite has a low coefficient of thermal expansion and high thermal conductivity, making it useful in high-temperature applications.

Fluorite powder is available in various grades and particle sizes, depending on its intended use.

It can be used as a raw material in the production of metallurgical flux, ceramics, and glass, or as an additive in the manufacture of plastics, rubber, and other materials.

It can also be used as a filler in paints, coatings, and other industrial products.

There are several advantages to using a fluorite powder high pressure suspension grinding mill for fluorite powder processing:

High efficiency

Low energy consumption

High fineness

Wide range of applications

Low noise

Long service life

Protect the environment

High efficiency: The fluorite powder high pressure suspension grinding mill can grind the fluorite powder to a very fine particle size, which increases the efficiency of the subsequent processing steps.

Low energy consumption: The fluorite high pressure suspension grinding mill uses a high-pressure spring system to increase the pressure on the grinding roller and grinding ring, which reduces the energy consumption of the mill.

High fineness: The high pressure suspension grinding mill can produce fluorite powder with a very high fineness, which can be adjusted according to the needs of the application.

Wide range of applications: Fluorite powder processed by the high pressure suspension grinding mill has a wide range of applications in industries such as metallurgy, chemical engineering, ceramics, and glass making.

Low noise: The high pressure suspension grinding mill operates with low noise, making it suitable for use in environments where noise levels need to be controlled.

Long service life: The grinding roller and grinding ring of the high pressure suspension grinding mill are made of high-quality materials, which have a long service life and can reduce maintenance costs.