Table of Contents

CLUM series graphite powder vertical ultrafine powder grinding mill are suitable for huge capacity producing, widely used in grinding non-flammable and non-explosive materials under 9.3(the Moh’s hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc.

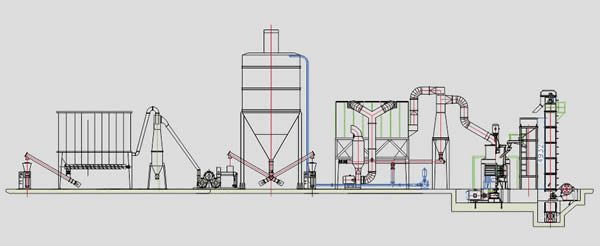

CLUM series graphite powder vertical ultrafine powder grinding mill grinding disc is driving by motor through reducer. The material falls to grinding disc from the feed opening. The materials are driven to the edge of disc by the centrifugal force and crushed into fine powders by rollers. Then, the hot air from the nozzle take the fine powder to high effiency classsifer.The qualified powder are taken by the air to the powder collector to be collected, while the unqualified powder are sent back for regrinding.

1. High grinding efficiency: save 20~30% power consumption compared with the ball mill. With the increase of moisture content, it can save more and more electricity.

2. Strong drying capacity: dry and grind raw materials with moisture content as much as 15%.

3. Mutifunction: crushing, drying, grinding, separating and conveying.

4. Low noises and little dust: no direct contact between the grinding rollers and grinding disc, so metallic impact is avoided and its noise is 20~25 decibels lower. Totally closed negative pressure operation has been employed by this vertical grinding mill, so there is no dust during the operation.

5. Low wear rate and little metallic pollution: its metal wear is only 5~10g/t.

• Good quality of finished products

• Advanced control system, saving labor force

• 3000 mesh calcium carboante powder grinding mill machine have CE, ISO9001

• Factory sell directly

• 30 years experience, professional

• Low noises, less dust, environmental protection

• Low wear rate, less metallic pollution, long service life

• Strong drying capacity: drying and grinding raw materials with a moisture content of up to 15%

| Main Configuration and Production | |||

| Model | CLUM1425 | CLUM1632 | CLUM1736 |

| Working Diameters(mm) | 1400 | 1600 | 1700 |

| Number of rollers(pieces) | 3 | 3 | 3 |

| Number of classifier(pieces) | 5 | 7 | 7 |

| Power of classifier(Kw) | 5X15 | 7X15 | 7X(15~18.5) |

| Main unit power (Kw) | 250 | 315 | 355 |

| Blower power(Kw) | 200 | 250 | 315 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

| Less than 2μm=34% output(t/h) |

11-14 | 13-17 | 15-19 |

| Less than 2μm=46% output(t/h) |

7-8 | 9-10 | 11-12 |

| Less than 2μm=60% output(t/h) |

3-4 | / | / |

| Material: based on calcite Particle size distribution: measured by micro laser diffraction particle size analyzer in British Malvern3000 instruments |

|||

Shanghai Clirik Machinery Co., Ltd, located in Pudong New Area of Shanghai, China, is a large professional manufacturer with import & export rights specializing in research, manufacture and sales of crushing machinery, mining equipment, and grinding machines.

Whether you need micro powder grinding equipment, ultrafine grinding equipment, stone grinding equipment, mineral grinding machine, hammer crushers, jaw crushers and associated accessories, we have the perfect solution for your unique requirements.

Services For You:

1. One year guarantee for the whole machine except for wear parts; 2.24 hours technical support by email;

2. Calling service;

3. User manual available;

4. Reminding for the service life of the wearing parts;

5. Installation guide for clients from both China and abroad;

6. Maintenance and replacement service;

7. Whole process training and guidance from our technicians.

The high quality of after-sales service symbolizes our brand and ability. We pursue not only good quality products, but also best after sales service. Your satisfaction is our final purpose.

1. Q: Can your CLUM series graphite powder vertical ultrafine powder grinding mill process the slag and other hard materials?

A: Our grinding parts of the vertical roller mill are made of hard materials, so it can be used in slag, cement and other hard materials grinding.

2. Q: What is the fineness range of the CLUM series graphite powder vertical ultrafine powder grinding mill?

A: It can be adjusted between 325 mesh to 3500 mesh.

3. Q: Are you a manufacturer or middleman?

A: Our Shanghai Clirik is a professional CLUM series graphite powder vertical ultrafine powder grinding mill manufacturer.

More Information Welcome to Leave Your Message to Inquiry.

4. Q: What other products can you offer?

In addition to providing ultra-fine vertical grinding mill machine, we can also provide you with crusher, ultra-fine grinding mill machine, elevator, modification powder machine and some other related mine mill grinding equipment.

Finished Size: 300-2500(mesh)

Capacity: 0.5-45(t/h)

Pass rate: D97 5 micron

Used to stone powder modification machine

Finished Size: 50-450(mesh)

Capacity: 1-28(t/h)

Pass rate: D90 30 micron