Table of Contents

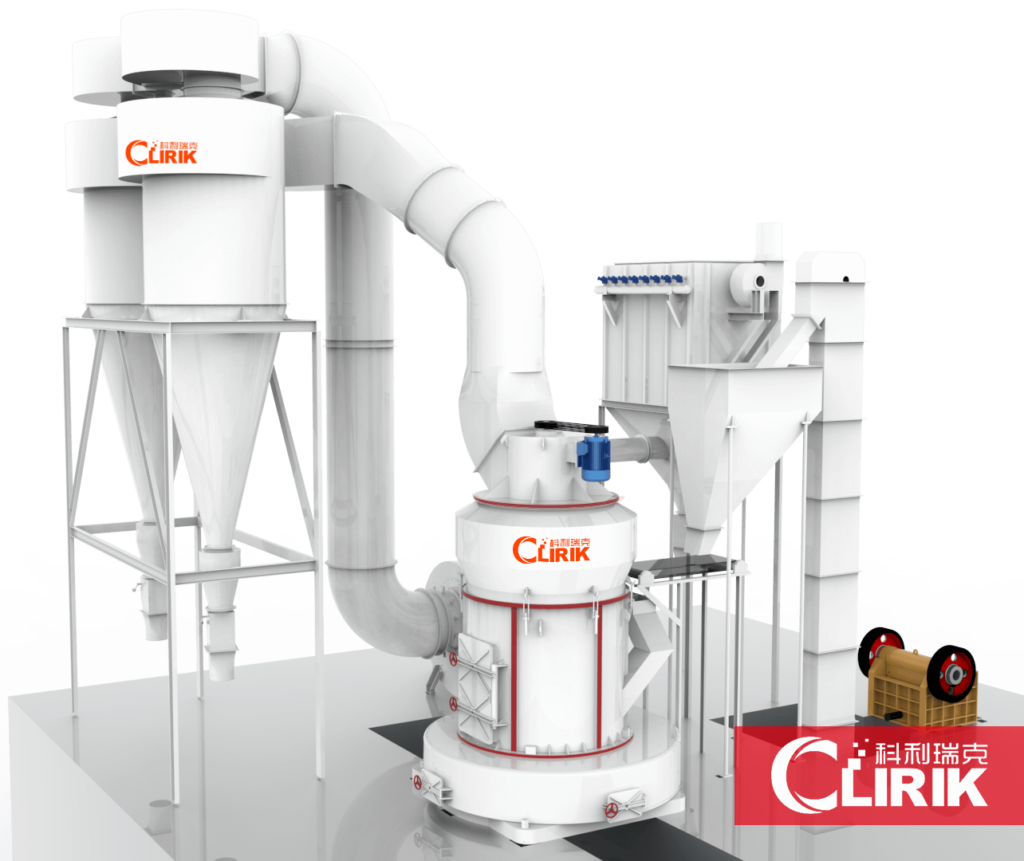

CLRM series enhanced roller grinding mill is suitable for processing various non-flammable and non- explosive mineral materials with Moh’s hardness less than 6 and humidity less than 6%. It is widely used in the fields of metallurgy, construction, chemical industry, mining, highway construction etc. The granularity of the finished powder size can be adjusted between 80 – 500 meshes (180- 30 micron). Examples of processing materials include quartz, feldspar, barite, calcite carbonate, limestone, talc, ceramic, iron ore, carborundum, bauxite, rock phosphate, coal and other materials, a total of about 400 kinds of materials.

CLRM series enhanced roller grinding mill

Finished Size: 80-300 mesh

MQQ: 1 Set

Price: 19999-69999 $

Capacity: 1-35 t/h

Max feeding size: 35 mm

Range of application: Calcium carbonate, quartz, feldspar, barite, calcite carbonate, limestone, talc, ceramic,iron ore, carborundum, bauxite, rock phosphate, coal…

CLRM series enhanced roller grinding mill components:

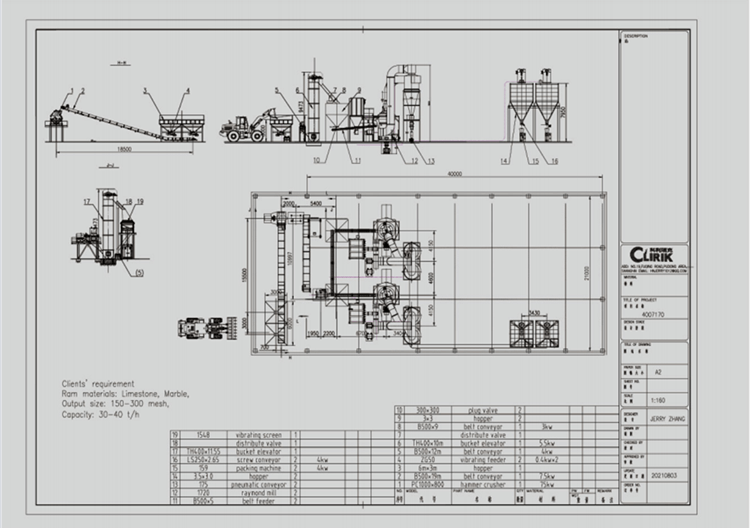

The standard configuration of the CLRM series enhanced roller grinding mill consists of main unit, reducer, powder classifier, cyclone percolator, dustcleaner, blower, electrical cabinet and pipes. The optional accessories include a crusher, bucket elevator, feeder.

CLRM series enhanced roller grinding mill workflow:

Big materials are crushed by crusher to the required particle sizes, and carried by bucket elevator to the storage hopper, and are fed evenly and continuously by vibrating feeder into the main unit for grinding. The grinded powder is carried by the airflow from the blower to the cassifier to be classified, the particles which meet the fineness enter cyclone collector through pipe, are separated and collected there. They are discharged at the discharging valve to become finished products; the airflow is sucked to the blower by a return pipe on the top of a cyclone collector. The whole airflow system is a sealed circulation, and is circulated under positive and negative air pressure.

1. Optimized grinding part, increase grinding efficiency.

Compared with the previous mill, the grind pressure increased 10%, grinding area up 15 -20%. Optimized the roller layout, escalated the efficient grinding space.

2. Triple vibrating damping for working stability.

Triple damping to resist the vibrating transmit in the main unit base, volute aiflow house, unit body, grinding part. Be sure of the stable grinding condition.

3. New type impeller of cassifier with VFD.

Equipped the new cage type impeller for lassifier, adjust the speed freely by VFD, enlarge the output size range to 80 425 mesh.

4. Grinding device adopts superimposed multistage seal, prolong the lubricating cycle.

Make CLRM series enhanced roller grinding mill the maintenance convenient, cost saving.

| Model | Roller | Ring | Main Shaft Speed (r/min) |

Feeding Size (mm) |

Finished Size (mesh) |

Motor (kw) |

Capacity (t/h) |

||

| Quantity (piece) |

Size (mm) |

External Dia (mm) |

Height (mm) |

||||||

| CLRM9720 | 3-4 | 320*200 | 1077 | 200 | 145 | <20 | 80-500 | 45*15*37 | 1-7 |

| CLRM1280 | 3 | 370*2*40 | 1280 | 240 | 125 | <20 | 80-400 | 75*15*55 | 2-12 |

| CLRM1300 | 4 | 410*2*80 | 1390 | 280 | 112 | <20 | 80-400 | 110*22*90 | 3-15 |

| CLRM1620 | 4 | 450*300 | 1620 | 300 | 102 | ><20 | 80-400 | 160*30*132 | 5-20 |

| CLRM1700 A | 4 | 510*300 | 1700 | 300 | 102 | <30 | 80-325 | 185*37*160 | 6-25 |

| CLRM1720 | 4 | 510*300 | 1850 | 300 | 92 | <35 | 80-325 | 250*45*185 | 6-25 |

| CLRM1900 A | 4 | 600*300 | 1900 | 300 | 92 | <35 | 80-325 | 250*45*220 | 8-32 |

| CLRM2150 | 4 | 600*300 | 2150 | 300 | 85 | <35 | 80-325 | 315*45*280 | 12-35 |

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai, China, is a pioneer enterprise, which is specializing in research, manufacture and sales of all kinds of grinding mill, all kinds of crushers from coarse grinding mill, fine grinding mill and ultra fine grinding mill, grinding mill related equipment, such as powder modifying machine, powder packing machine. powder conveying system, etc.

We have devoted ourselves to the grinding field for more than 30 years. We believe only focus can be professional. Our company has already formed a full set of modern production lines, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

1. How long is the warranty of your CLRM series enhanced roller grinding mill? Do you supply spare parts?

Our warranty period is generally one year. We can supply spare parts.

2. Do you provide equipment operation training?

Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

3. Are you a trading company or manufacturer?

We are a factory.You can enjoy the factory price when you buy our equipment.

4. How long is your delivery time?

Generally, it is 10-15 days if the goods are in stock.

or it is 15-25 days if the goods are not in stock, it is according to quantity.

5.If we need to build a complete ore powder production line can you provide all the equipment?

Yes, we can help you set up a complete production line and give you related professional advice. We have already built many mining projects in China & overseas.