Table of Contents [hide]

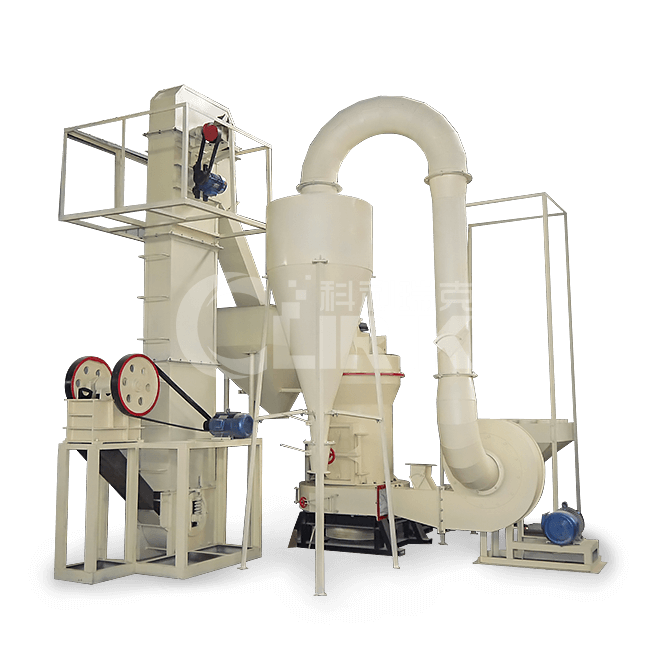

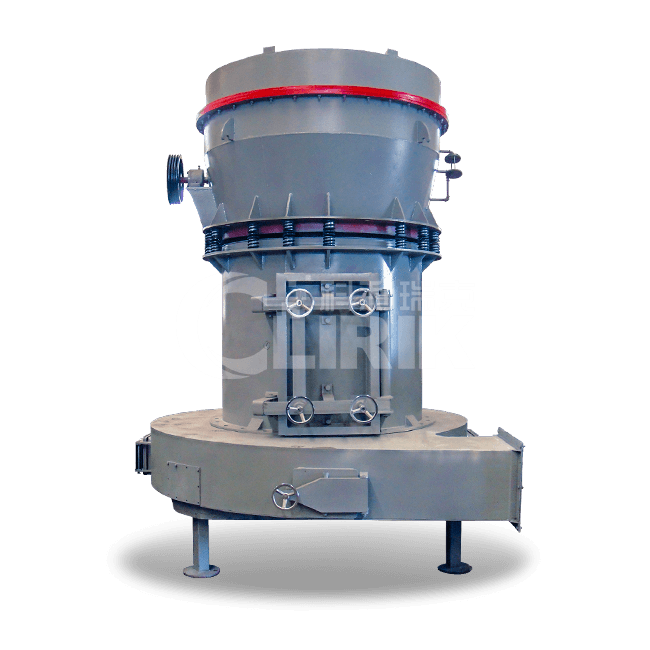

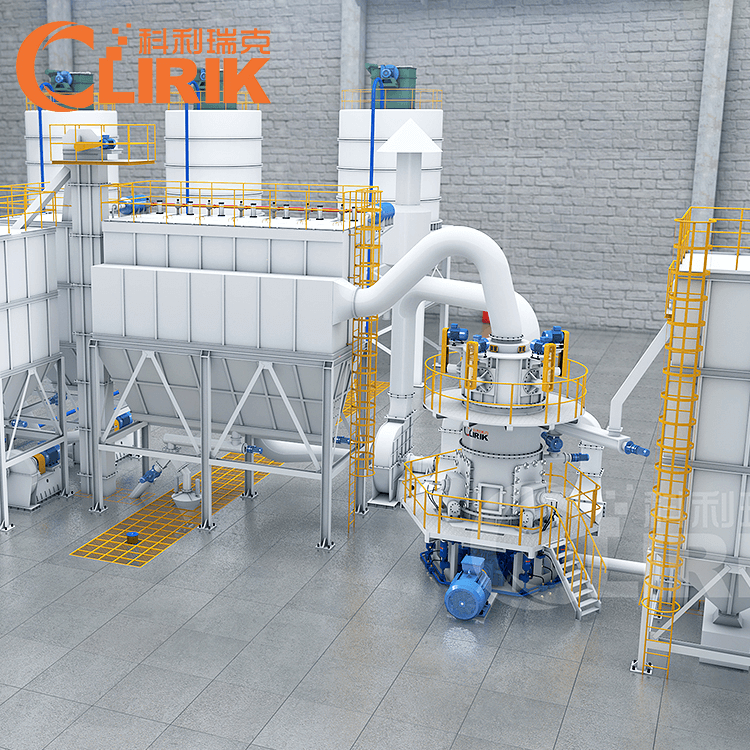

A bauxite vertical powder ultrafine grinding mill is a specialized machine used for grinding bauxite into fine and ultrafine powders. These mills are essential in various industries, particularly in the production of alumina, refractories, and ceramics. Here are the key components and features of such a mill:

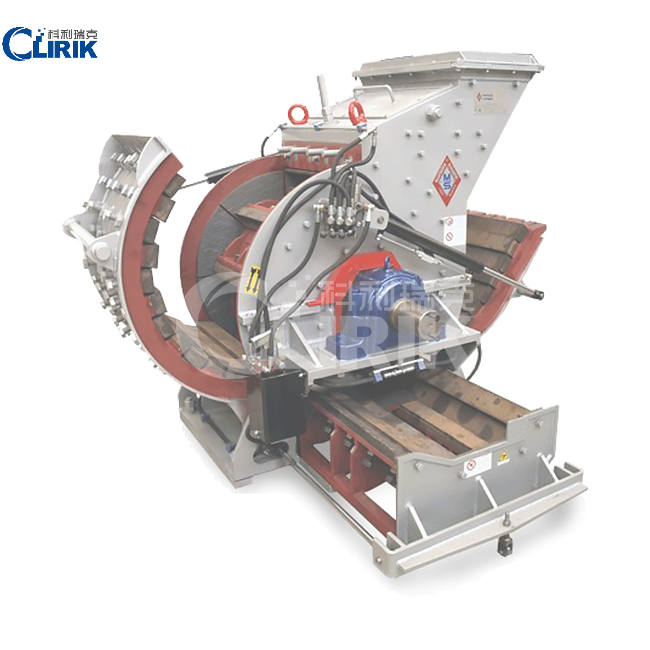

1. Grinding Rollers: Vertical mills typically have multiple rollers that rotate around a vertical axis, applying pressure to the material being ground.

2. Grinding Table: The material to be ground is fed onto a rotating grinding table. The rollers crush and grind the material against the table.

3. Classifier: This component ensures that only particles of the desired size are allowed to exit the mill, returning larger particles for further grinding.

4. Hydraulic System: Used to apply pressure to the rollers and control the grinding process.

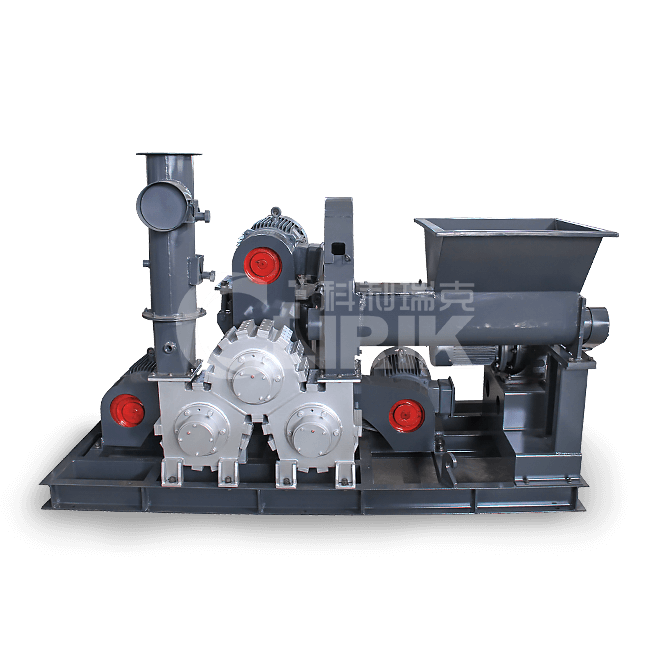

5. Feeding System: Ensures consistent and controlled feeding of bauxite into the mill.

6. Drive System: Powers the grinding table and rollers.

7. Dust Collection System: Captures fine particles and maintains a clean working environment.

1. High Efficiency: Bauxite vertical powder ultrafine grinding mill are highly efficient due to the effective grinding mechanism and energy-saving design.

2. Fine and Ultrafine Grinding: Capable of producing powders with particle sizes down to a few microns, suitable for various applications.

3. Consistent Product Quality: The integrated classifier ensures uniform particle size distribution.

4. Large Capacity: Suitable for large-scale production due to their robust design and high throughput.

5. Low Maintenance: Designed for durability and ease of maintenance, with components that are easily accessible for servicing.

6. Environmental Friendly: Equipped with dust collection systems and designed to minimize noise and vibration.

1. Material Feeding: Bauxite is fed into the mill through the feeding system.

2. Grinding: The rotating table and rollers exert force on the material, crushing and grinding it into fine powder.

3. Classification: Ground material is classified by the integrated classifier, which separates fine particles from larger ones.

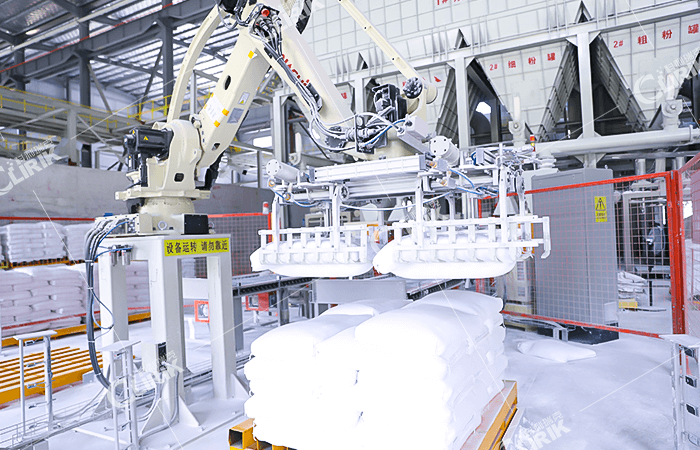

4. Collection: Fine powder is collected and transported to the next stage of processing or packaging.

Example Specifications

Feed Size: Typically up to 30 mm

Product Fineness: D97 = 10-45 µm

Capacity: Ranges from a few hundred kilograms per hour to several tons per hour, depending on the model.

Power Consumption: Energy-efficient designs with power consumption in the range of 100-500 kW, depending on capacity and model.

This type of mill is crucial in ensuring the efficient and high-quality production of bauxite powders needed in various industrial applications.

| Main Configuration and Production | |||

| Model | CLUM1425 | CLUM1632 | CLUM1736 |

| Working Diameters(mm) | 1400 | 1600 | 1700 |

| Number of rollers(pieces) | 3 | 3 | 3 |

| Number of classifier(pieces) | 5 | 7 | 7 |

| Power of classifier(Kw) | 5X15 | 7X15 | 7X(15~18.5) |

| Main unit power (Kw) | 250 | 315 | 355 |

| Blower power(Kw) | 200 | 250 | 315 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

| Less than 2μm=34% output(t/h) |

11-14 | 13-17 | 15-19 |

| Less than 2μm=46% output(t/h) |

7-8 | 9-10 | 11-12 |

| Less than 2μm=60% output(t/h) |

3-4 | / | / |

| Material: based on calcite Particle size distribution: measured by micro laser diffraction particle size analyzer in British Malvern3000 instruments |

|||

The bauxite vertical powder ultrafine grinding mill offers several advantages that make it a preferred choice for industrial applications involving bauxite processing. Here are the key advantages:

1. High Grinding Efficiency

(1) Enhanced Grinding Mechanism: The vertical design and the pressure applied by the rollers ensure efficient grinding, resulting in higher productivity and reduced energy consumption.

(2) Optimized Grinding Conditions: Bauxite vetical powder ultrafine grinding mill often have a more effective grinding mechanism due to the consistent pressure applied by multiple rollers.

2. Energy Saving

(1) Reduced Power Consumption: The vertical design typically requires less energy compared to traditional ball mills. This results in lower operational costs.

(2) Efficient Energy Use: The vertical mill’s design maximizes the use of energy, reducing waste and improving overall energy efficiency.

3. Consistent Product Quality

(1) Uniform Particle Size: The integrated classifier ensures that the ground product has a consistent particle size distribution, which is critical for various applications.

(2) Stable Operation: The design of the vertical mill allows for stable operation, leading to consistent product quality over time.

4. Large Capacity

(1) High Throughput: Bauxite vertical powder ultrafine grinding mill can handle large volumes of material, making them suitable for high-capacity production environments.

(2) Scalability: These mills can be scaled up to meet the demands of larger operations without significant changes to the process.

5. Low Maintenance

(1) Durable Components: The components of a Bauxite vertical powder ultrafine grinding mills are designed for durability and long life, reducing the frequency and cost of maintenance.

(2) Ease of Access: Vertical mills are designed with maintenance in mind, allowing easy access to components for inspection and repairs.

6. Environmental Benefits

(1) Dust Collection: Equipped with advanced dust collection systems, vertical mills help maintain a cleaner working environment by capturing fine particles.

(2) Noise and Vibration Reduction: The design of Bauxite vetical powder ultrafine grinding mills often incorporates features that reduce noise and vibration, contributing to a safer and more pleasant working environment.

7. Flexibility in Applications

(1) Versatility: Bauxite vertical powder ultrafine grinding mills can grind a wide variety of materials besides bauxite, such as limestone, calcite, and other minerals, making them versatile machines for different industries.

(2) Adaptability: They can be easily adjusted to meet specific grinding requirements, such as varying fineness levels and production rates.

8. Compact Design

(1) Space-Saving: The vertical orientation of these mills means they take up less floor space compared to horizontal mills, making them ideal for facilities with limited space.

(2) Integrated Systems: Many Bauxite vertical powder ultrafine grinding mills come with integrated systems for feeding, grinding, and classifying, further reducing the space needed for additional equipment.

9. Automation and Control

(1) Advanced Control Systems: Many modern Bauxite vertical powder ultrafine grinding mills are equipped with advanced automation and control systems that enhance operational efficiency and reduce the need for manual intervention.

(2) Real-Time Monitoring: These systems allow for real-time monitoring of the grinding process, enabling quick adjustments to maintain optimal performance.

Maintaining a bauxite vertical powder ultrafine grinding mill is crucial to ensure its efficiency, longevity, and consistent performance. Here are detailed maintenance steps and best practices:

1. Regular Inspections

(1) Daily Checks: Inspect the bauxite vertical powder ultrafine grinding mill for any visible signs of wear or damage. Check for unusual noises or vibrations.

(2) Weekly Inspections: Inspect the rollers, grinding table, and classifier for wear and tear. Ensure all bolts and connections are tight.

(3) Monthly Inspections: Conduct a more thorough inspection, including checking the hydraulic system, lubrication points, and dust collection system.

2. Lubrication

(1) Regular Lubrication: Ensure that all moving parts are properly lubricated according to the manufacturer’s recommendations. This includes the rollers, grinding table bearings, and other moving components.

(2) Oil Changes: Change the oil in the hydraulic system and other lubricated parts at intervals specified by the manufacturer.

3. Grinding Rollers and Table Maintenance

(1) Wear and Tear Monitoring: Regularly check the wear patterns on the grinding rollers and table. Replace worn parts as needed to maintain grinding efficiency.

(2) Balancing: Ensure the rollers and table are properly balanced to prevent vibrations and uneven wear.

4. Hydraulic System

(1) Pressure Checks: Regularly check the hydraulic pressure to ensure it is within the specified range. Adjust as necessary.

(2) Leak Inspections: Inspect the hydraulic system for leaks. Repair any leaks promptly to prevent damage and maintain pressure.

5. Classifier Maintenance

(1) Blade Inspection: Inspect the classifier blades for wear and damage. Replace blades if they are worn out or damaged.

(2) Adjustment: Ensure the classifier is properly adjusted to maintain the desired particle size distribution.

6. Dust Collection System

(1) Filter Checks: Regularly inspect and clean or replace filters in the dust collection system to maintain optimal airflow and dust capture.

(2) System Integrity: Check the dust collection ducts and seals for any leaks or blockages.

7. Drive System

(1) Belt and Gear Checks: Inspect belts and gears for wear and tension. Replace worn belts and adjust tension as necessary.

(2) Motor Maintenance: Ensure the motor is operating smoothly without overheating. Lubricate motor bearings as recommended.

8. Cooling System

(1) Coolant Levels: Check coolant levels in the cooling system and top up as needed.

(2) Heat Exchangers: Inspect heat exchangers for blockages and clean them to ensure efficient cooling.

9. Control System

(1) Software Updates: Keep the control software up to date to ensure optimal performance and security.

(2) Calibration: Regularly calibrate sensors and control instruments to maintain accuracy.

10. Operator Training

(1) Regular Training: Ensure operators are trained on the proper use and maintenance of the mill. Regular training updates can help prevent operational errors.

(2) Maintenance Procedures: Train operators on routine maintenance procedures and troubleshooting common issues.

11. Spare Parts Inventory

(1) Stock Critical Parts: Keep an inventory of critical spare parts, such as rollers, grinding table segments, hydraulic seals, and classifier blades.

(2) Supplier Contacts: Maintain contact information for suppliers to quickly order parts when needed.

12. Documentation

(1) Maintenance Logs: Keep detailed logs of all maintenance activities, including inspections, part replacements, and lubrication schedules.

(2) Manufacturer Guidelines: Follow the manufacturer’s maintenance guidelines and schedules to ensure the mill operates as intended.

13. Safety Measures

(1) Lockout/Tagout: Implement lockout/tagout procedures to ensure the mill is safely powered down during maintenance.

(2) Personal Protective Equipment (PPE): Ensure maintenance personnel wear appropriate PPE, such as gloves, safety glasses, and hearing protection.

Regular and thorough maintenance of the bauxite vertical powder ultrafine grinding mill not only enhances its performance and longevity but also ensures safe and efficient operation. Following these best practices can help prevent unexpected breakdowns and maintain high productivity.

Clirik has several advantages in producing Bauxite vertical powder ultrafine grinding mill, including:

1. High efficiency and energy saving: Clirik’s grinding mill adopts advanced design and manufacturing technology, which can greatly improve the grinding efficiency while reducing energy consumption, making it more energy-saving and environmentally friendly.

2. Adjustable fineness: The Bauxite vertical powder ultrafine grinding mill can produce powders of different finenesses, from coarse powder to ultrafine powder. The fineness can be adjusted between 325 mesh and 2500 mesh to meet different application needs.

3. High stability: Clirik’s equipment has high stability and reliability, low vibration and noise during operation, easy maintenance and low failure rate.

4. Large output: The equipment is reasonably designed and has strong production capacity. It can meet the needs of large-scale production and is suitable for large enterprises.

5. Environmental protection design: Equipped with dust removal equipment, it can effectively control dust emissions, meet environmental protection standards, and reduce pollution to the environment.

6. Intelligent control: The grinding mill adopts PLC control system, which is simple and convenient to operate, can realize automatic control, improve production efficiency and reduce labor costs.

7. Strong durability: key components are made of high-strength materials, with a long service life, reducing the cost of equipment maintenance and replacement.

Through these advantages, Clirik’s Bauxite vertical powder ultrafine grinding mill can provide customers with efficient, environmentally friendly and stable grinding solutions to meet the needs of a variety of industrial applications.