Table of Contents

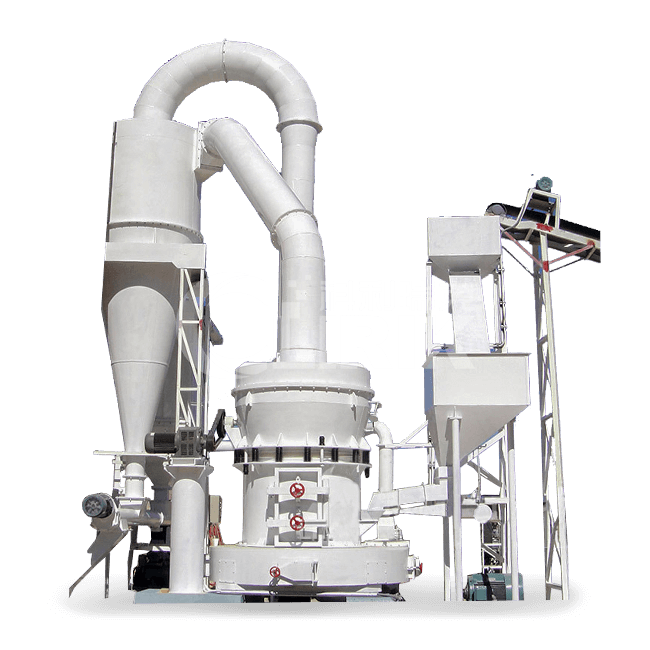

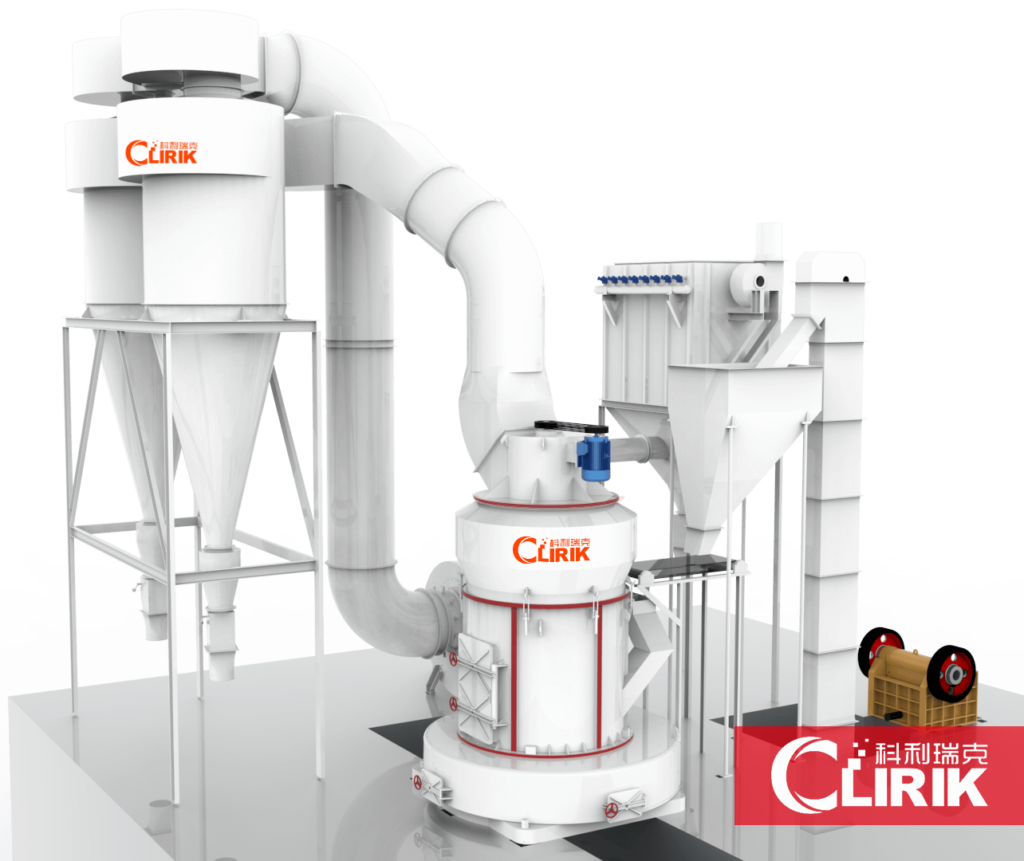

Bauxite powder Raymond mill also called bauxite powder Raymond roll mill,Widely used in metallurgy, building materials, chemical industry, mining and other fields of mineral materials grinding processing, suitable for processing mohs hardness below 6, humidity below 6% of all kinds of non-flammable and explosive minerals, Such as gypsum, talc, calcite, limestone, marble, potassium feldspar, barite, dolomite, granite, kaolin, bentonite, medical stone, bauxite, iron oxide red, iron ore, etc.,

Bauxite Powder Raymond Mill has the following advantages in adding Bauxite stone powder:

1. High efficiency and energy saving: Bauxite Powder Raymond Mill adopts an optimized design, which makes the energy consumption lower and the efficiency higher at the same output, which helps to reduce production costs.

2. High-precision grinding capacity: Bauxite Powder Raymond Mill can grind Bauxite to a wide range of fineness (usually between 50-325 mesh), suitable for different application needs, especially the preparation of high-precision powder.

3. Reasonable structural design: The machine has a compact structure and a small footprint, which is easy to install and maintain, reducing the floor space of the production line.

4. Environmental design: The equipment is equipped with a dust removal device and a muffler, which reduces dust emissions and noise pollution during the production process and meets environmental protection requirements.

5. Strong durability: Using high-quality wear-resistant materials, core components such as grinding rollers and grinding rings have a long life, reducing the maintenance frequency and downtime of the equipment.

6. High degree of automation: Equipped with an intelligent control system, it can realize remote monitoring and automatic operation, improving the overall management efficiency of the production line.

These advantages make Clirik’s Bauxite Powder Raymond Mill highly competitive in the market, especially in the field of high-quality powder production.

The working principle of a Bauxite Powder Raymond Mill is based on the grinding and crushing mechanism that utilizes the centrifugal force generated by the rotating rollers to grind the material against a grinding ring. Here’s a detailed explanation of how it works:

1. Material Feeding: Bauxite raw material is first fed into the hopper of the Raymond Mill by a vibrating feeder. The material is then transferred to the grinding chamber for processing.

2. Grinding Process: Inside the grinding chamber, the material is crushed and ground by the rollers. These rollers are suspended on a horizontal axis and rotate around the central axis due to the centrifugal force generated by the rotation of the main shaft. The material is pushed down onto the grinding ring where it is ground into fine particles by the rolling rollers.

3. Classifying Process: The ground material is carried by a stream of air generated by the blower to the classifier located at the top of the mill. The classifier separates the fine powder from the coarse particles. Fine powder is collected as the final product, while coarse particles are returned to the grinding chamber for further grinding.

4. Collection Process: The fine bauxite powder is collected through a cyclone separator and discharged through the powder discharge valve. Any remaining dust is captured by the dust collector to ensure the environment remains clean and pollution-free.

5. Air Circulation: The blower is responsible for circulating the air within the Bauxite Powder Raymond Mill, ensuring that the material is continuously ground and classified. Excess air is expelled after passing through the dust collector, while the clean air is recirculated back into the grinding chamber.

6. Control System: The Bauxite Powder Raymond Mill is typically equipped with an automatic control system that regulates the grinding process, ensuring consistent output and optimizing energy efficiency.

This process allows the Bauxite Powder Raymond Mill to effectively grind bauxite into a fine powder, which can then be used in various industrial applications such as aluminum production, refractory materials, and ceramics.

| Model | Roller | Ring | Feeding Size(mm) |

Finished Size(mm) |

Mill System Power(KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

| Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1.0-3.0 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12.0 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16.0 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8.0-20.0 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28.0 | 11550*9500*1050 |

Bauxite powder is a kind of fine powdery material obtained by crushing and grinding bauxite. Bauxite is the main raw material for refining aluminum and contains rich alumina (Al₂O₃), which is usually reddish brown or grayish-white. Bauxite powder is widely used in aluminum smelting, refractory materials, ceramics, chemical and other industries. In the aluminum production process, bauxite powder through the Bayer process or molten salt electrolysis and other processes, and finally extract pure aluminum.

Bauxite powder advantages

1. High alumina content: Bauxite powder is rich in alumina (Al₂O₃), which is an important raw material for aluminum production and has high economic value.

2. Multi-purpose: Bauxite powder is not only used in aluminum smelting, but also widely used in refractory materials, ceramics, chemical and other fields, with a variety of industrial uses.

3. High temperature resistance: Bauxite powder has good high temperature resistance, especially suitable for the manufacture of high temperature kiln refractories and casting industry.

4. Strong chemical stability: bauxite powder has good chemical stability in acid and alkali environment, and can maintain its properties under harsh industrial conditions.

5. Rich resources: bauxite resources are relatively rich in the world, the mining and processing costs are relatively low, and the supply is stable.

These advantages make bauxite powder an important raw material in many industrial production.

1

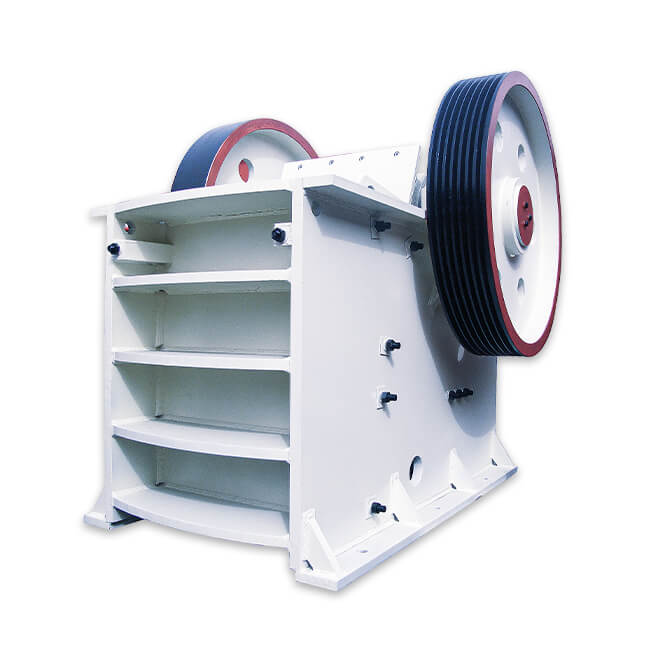

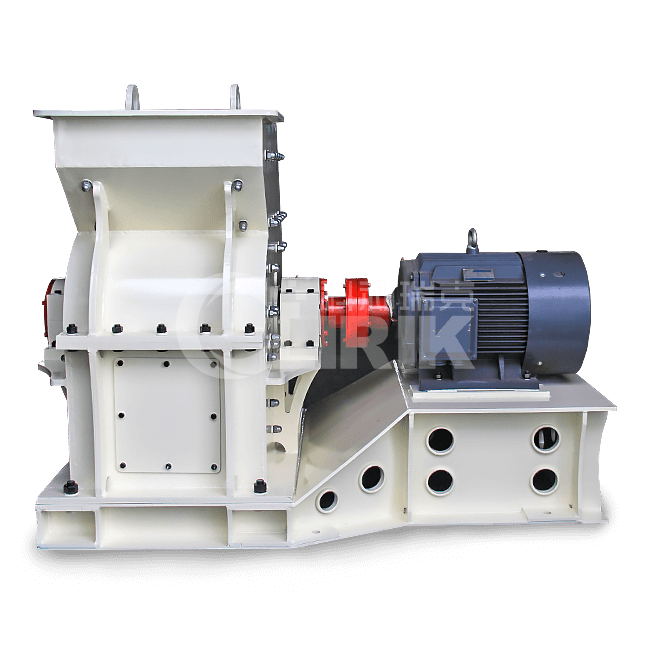

To process bauxite into powder, several machines are needed to complete the various stages of crushing, grinding, drying, and classification. Here’s a list of the essential machines:

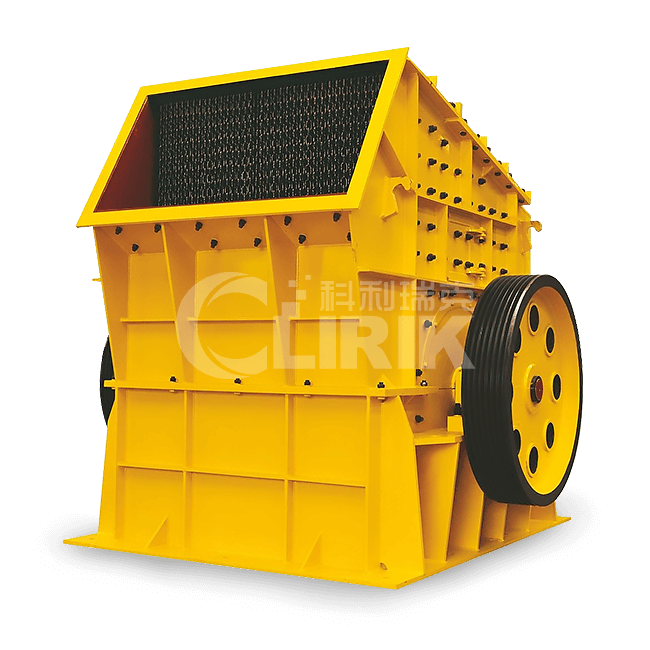

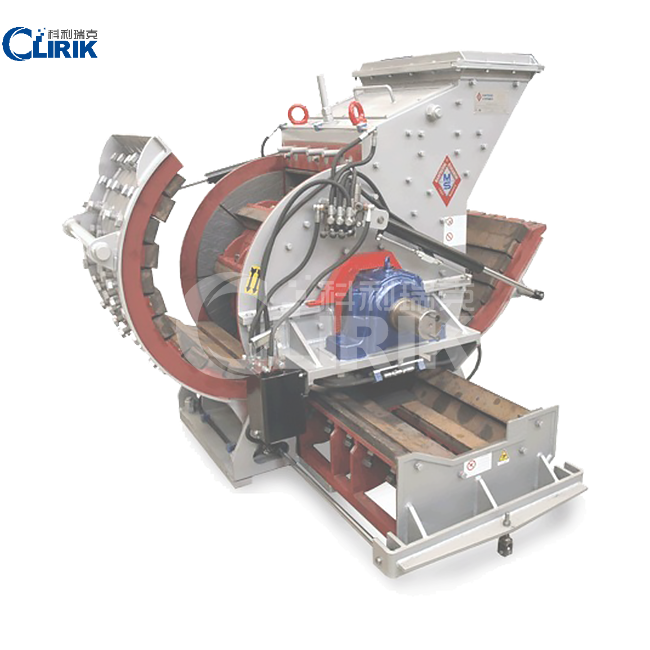

Crusher Equipment

Grinding equipment

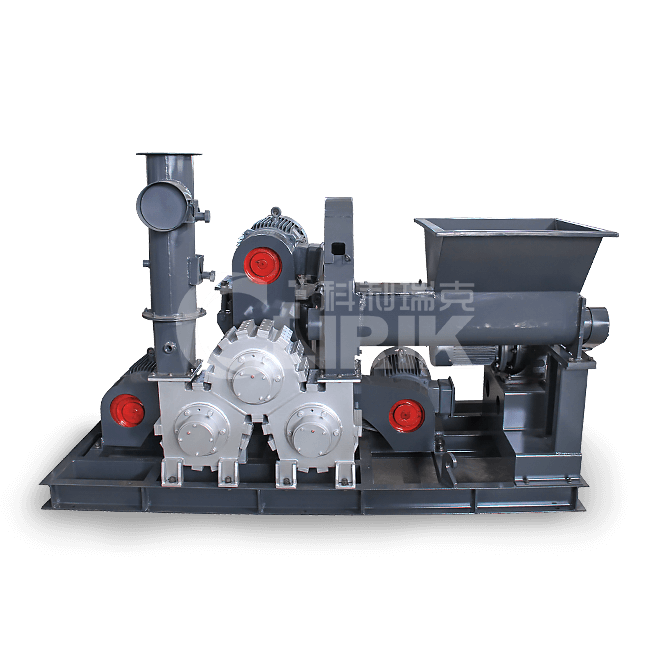

Other Equipment

Clirik has the following advantages in the production of Bauxite Powder Raymond Mill:

1. Rich Professional Experience: Clirik has many years of experience in the research, development, and production of powder equipment, especially in the design and manufacturing of barite grinding equipment, accumulating extensive technical and process experience.

2. Strong Technological Innovation: Clirik continuously innovates and improves, with its Bauxite Powder Raymond Mill adopting the latest grinding technology. This technology offers high efficiency, energy savings, and stable operation, meeting the market demand for high-quality barite powder.

3. Strict Quality Control: Clirik implements strict quality control throughout the production process, from raw material procurement to finished product delivery. Each step undergoes rigorous testing to ensure the equipment’s high reliability and durability.

4. Customized Services: Clirik offers various models of Raymond Mills and can provide customized equipment solutions according to the specific needs of customers, ensuring optimal equipment performance that meets production requirements.

5. Comprehensive After-Sales Service: Clirik provides comprehensive after-sales services, including installation guidance, operation training, regular maintenance, and technical support, helping customers use the equipment better and extend its lifespan.

6. Global Sales Network: Clirik’s products are sold in many countries and regions worldwide, giving it a broad market influence and enabling it to provide high-quality equipment and services to international customers.

These advantages position Clirik as a leader in the production of Bauxite Powder Raymond Mills, offering customers efficient and reliable powder solutions.

Maintaining a Bauxite Powder Raymond Mill involves several key practices to ensure its efficiency and longevity:

1. Regular Inspection

(1) Daily Checks: Inspect the bauxite powder Raymond mill’s wear parts, including the grinding roller, grinding ring, and other components. Look for signs of wear, cracks, or damage.

(2) Lubrication: Regularly check and replenish lubricating oil in the main engine, classifier, blower, and other transmission parts to ensure smooth operation.

2. Grinding Roller and Ring Replacement

(1) Replacement of wearing parts: Monitor the wear of the grinding rollers and rings, and replace them when necessary. Excessive wear can reduce grinding efficiency and cause vibration.

3. Cleaning

(1) Air Ducts: Ensure that the air ducts are free from blockages. Accumulation of material can cause reduced airflow and affect the separation efficiency.

(2) Blower: Clean the blower regularly to prevent dust build-up, which can lead to overheating and reduced performance.

(3) Feeding System: Keep the feeding system clean to avoid material clogging, which can cause uneven feeding and affect the mill’s output.

4. Check and Tighten Bolts

(1) Check and Tighten Bolts: Regularly inspect and tighten all bolts, especially on the grinding parts and the foundation of the mill. Loose bolts can lead to misalignment and excessive vibration.

5. Adjustment of the Classifier

(1) Adjustment of the Classifier: Adjust the classifier regularly to maintain the desired fineness of the bauxite powder. Changes in the classifier settings might be necessary as wear occurs.

6. Temperature Monitoring

(1) Temperature Monitoring: Continuously monitor the temperature of the main engine bearings and other critical components. Overheating can indicate excessive wear or insufficient lubrication.

7. Vibration Analysis

(1) Vibration Analysis: Perform regular vibration analysis to detect any abnormal vibrations, which could indicate misalignment, bearing failure, or other mechanical issues.

8. Filter Maintenance

(1) Filter Maintenance: Clean or replace the dust filters in the mill’s exhaust system to ensure proper ventilation and prevent dust accumulation.

9. Scheduled Overhauls

(1) Scheduled Overhauls: Schedule regular overhauls of the mill to inspect and repair all components, ensuring the long-term reliability of the equipment.

10. Operational Parameters

(1) Operational Parameters: Maintain consistent operational parameters such as feeding size, feeding rate, and air volume. Deviations can lead to suboptimal grinding performance.

Regular maintenance not only extends the life of the bauxite powder Raymond mill but also ensures consistent production quality and efficiency when grinding bauxite powder.