Table of Contents

The chemical composition of diatomite is mainly amorphous SiO2, containing a small amount of Fe2O3, MgO, Al2O3, K2O and organic impurities.

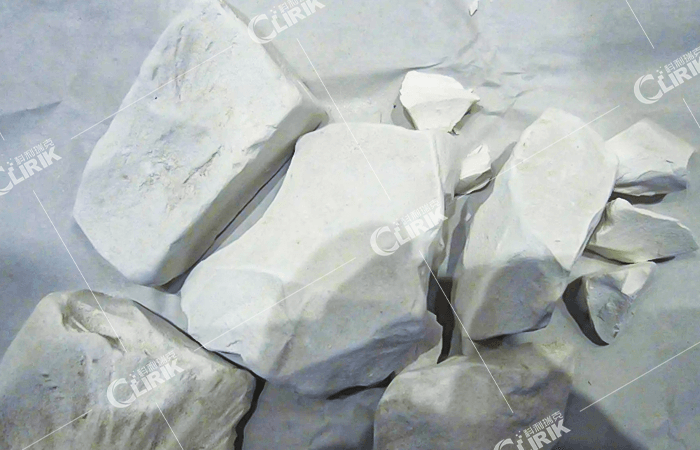

Diatomite is usually white, off-white, light yellow or light gray, and the bulk density is 0.34~0.65g/cm3. Melting point 1650 ℃ ~ 1750 ℃; specific surface area 19~65cm2/ g; pore volume 0.45 ~ 0.98 cm/g; water absorption rate is 2 to 4 times its own volume. High chemical stability, insoluble in hydrochloric acid, easily soluble in alkali, physical properties with soft, sound insulation, wear resistance, heat resistance, water absorption and many other excellent performance.

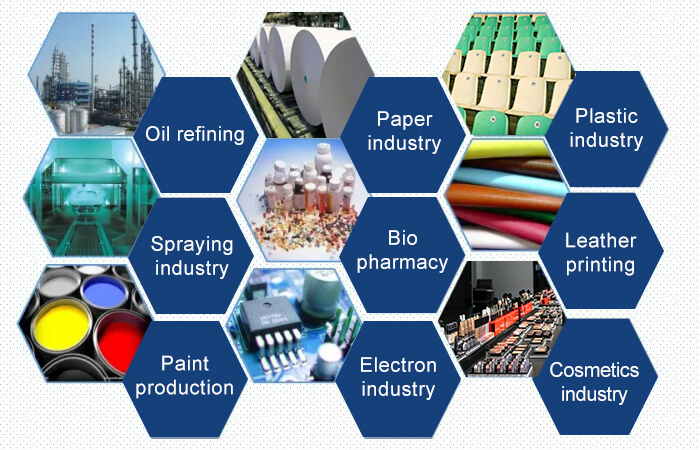

Many people think that diatomite can only be used for the decoration of the room. In fact, there are many. Diatomite is mainly used as filler, filter aid, catalytic carrier, adsorbent, environmental building materials and so on.

1. Diatomite can effectively absorb formaldehyde, and also has strong adsorption capacity for benzene, ammonia and other harmful gases. This is because of its own unique “molecular sieve” shaped pore layout, with strong filtering and adsorption, can effectively solve the problem of modern household air pollution.

2. Diatomite can also automatically adjust the humidity of indoor air. When the temperature changes in the morning and evening or the seasons change, diatomite can automatically absorb and release water according to the humidity in the air, so as to achieve the purpose of adjusting the humidity of the ambient air.

3. Negative oxygen ions released by diatomite can effectively remove a variety of odors, such as second-hand smoke, household garbage odor, pet odor and so on, and keep indoor air fresh.

4. Diatomite has the property of oil absorption. When it breathes, it can absorb oil molecules and react to release substances harmless to human body.

5. Diatomite is a good thermal insulation material because its main component is silicon dioxide, and its low thermal conductivity makes it suitable for heat insulation material.

Diatomite is often used as a filter aid because of its adsorption and filter properties.

Diatomite is very important in tires, tapes, cables and other rubber products. Because pure rubber products are easy to be harmed and lose their use value in the process of processing, use and storage, adding diatomite to them can effectively enhance its elasticity and strength. And diatomite is added in plastic products, can enhance heat resistance and wear resistance.

When producing paper, adding diatomite can widen the area of the light scattering interface of the paper, so as to enhance the transparency of the paper, so that the paper is glossy and has good strength. And the effect of diatomite can absorb the impurities produced in the papermaking process, the paper produced clean and white.

Diatomite is widely used in oil paint, powder paint and water-based paint and other coatings. Adding diatomite coating is not only non-toxic, light and soft, but also can improve the adhesion between the coating, speed up the drying speed of the coating, is a high-quality filler in the coating.

With the development of technology and product upgrading, diatomite will be widely used in emerging industries in the future. Let us recommend some super fine grinding machine for grinding diatomite powder for you!

CLUM Series Ultrafine Vertical Roller Mill

Advantage

High grinding efficiency: save 20~30% power consumption compared with the ball mill.

Strong drying capacity: dry and grind raw materials with moisture content as much as 15%.

Mutifunction: crushing, drying, grinding, separating and conveying.

Low noises and little dust: no direct contact between the grinding rollers and grinding disc, so metallic impact is avoided and its noises is 20~25 decibels lower. Totally closed negative pressure operation has employed by this vertical grinding mill, so there is little dust during the operation.

Low wear rate and little metallic pollution: its metal wear is only 5~10g/t.

HGM Series Ultrafine Powder Grinding Mill

Advantage

Energy Saving: Compare with the comon stone powder grinding machine, the HGM minerals grinding machine can decrease about 20%~30% electrinic consums

Long Service Life: Because the grinding ring and roller are forged by special material with high utilization. Under the same grinding material and finish special size, the lifecycle of spare parts is about one year, which is 2-3 times longer than impact mill or turbo mill

Environment Friendly: The application of pulse bag filter and muffler greatly alleviates dust pollution and noise

Cheaper Price& High Quality: Because our Shanghai Clirik is the HGM series grinding machine manufacturer, so you can get machine from us in the cheapest price, and at the same time we also can supply the warmly after sale service