150-2500 mesh Powder Grinding Processing Line

Shanghai Clirik Machinery Co., Ltd. HGM series powder grinding mill is widely applied to paint, tyre, chemical, building construction, etc.. The capcaity can reach to 30t per hour and the finished fineness range from 150 mesh to 2500 mesh. So what about the whole processing line?

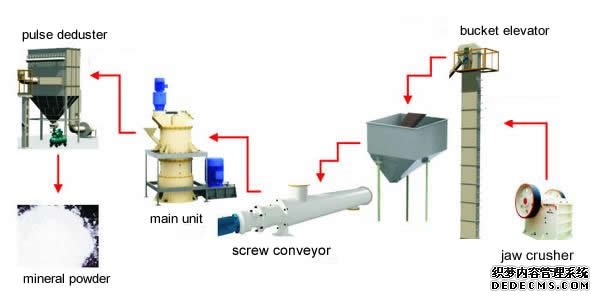

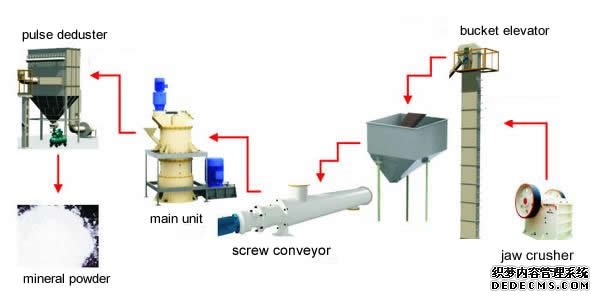

The whole powder processing line includes hammer crusher/jaw crusher, bucket elevator, hopper, screw feeder, grinder unit, in-built classifier, collector, pulse filter bag, discharging screw convey & valve, blower, muffler, air compressor, electrical control cabinet, sound-proof house.

For each parts, we will configurate different types and brand according to clients' practical needs.

Raw material was firstly crushed into small particles, and then sent to feeding hopper. With screw feeder, such particles will go into grinder unit and displaced on the upper turn-plate.

Turn-plate is turning around the middle axis, and the grinder connects with reducer box, it is driven by the grinder motor.

The powders will be grinded roller by roller, ring by ring, and fall down on the down turn-plate, and they will go through classifier with the airflow, as the high pressure produces negative wind.

All the powder will be classified by the high speed turning classifier impeller. Qualified one will go into collector and filter bags. Big one will fall down and be grinded again.

Most of the powders will fall into the collector, and few of them will go into bag house with the airflow. With the high pressure, the powder will fall down into screw conveyor and discharged from valve.

Should you have any questions of powder grinding mill, please feel free to contact me. You can dial our hot-line: 86-021-20236178 or send email to info@clirik.com for further detials.

The whole powder processing line includes hammer crusher/jaw crusher, bucket elevator, hopper, screw feeder, grinder unit, in-built classifier, collector, pulse filter bag, discharging screw convey & valve, blower, muffler, air compressor, electrical control cabinet, sound-proof house.

For each parts, we will configurate different types and brand according to clients' practical needs.

Raw material was firstly crushed into small particles, and then sent to feeding hopper. With screw feeder, such particles will go into grinder unit and displaced on the upper turn-plate.

Turn-plate is turning around the middle axis, and the grinder connects with reducer box, it is driven by the grinder motor.

The powders will be grinded roller by roller, ring by ring, and fall down on the down turn-plate, and they will go through classifier with the airflow, as the high pressure produces negative wind.

All the powder will be classified by the high speed turning classifier impeller. Qualified one will go into collector and filter bags. Big one will fall down and be grinded again.

Most of the powders will fall into the collector, and few of them will go into bag house with the airflow. With the high pressure, the powder will fall down into screw conveyor and discharged from valve.

Should you have any questions of powder grinding mill, please feel free to contact me. You can dial our hot-line: 86-021-20236178 or send email to info@clirik.com for further detials.