CLUM series vertical grinding mill supplier

CLUM series vertical grinding mill, which is developed and launched by Clirik, sets the medium crushing, drying, grinding, classifying and other functions as a whole, being the ideal equipment in the grinding industry.

Application of vertical grinding mill

CLUM series vertical grinding Mill can be widely applied to process large-scale ultra fine powder, encompassing calcite, marble, limestone, barite, talcum, kaolin, dolomite, wollastonite, gypsum, feldspar, pyrophyllite and other non-metallic minerals.

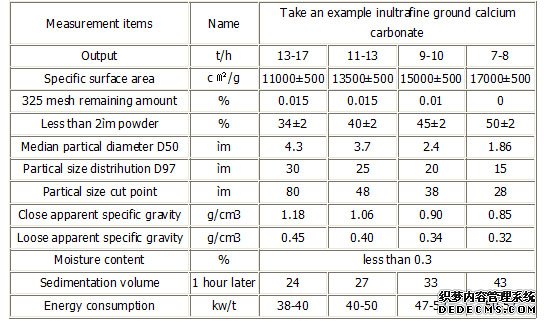

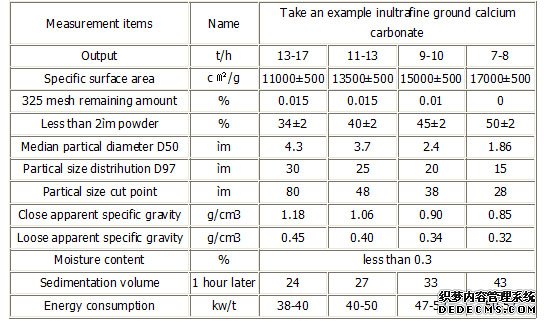

Specification of ultrafine powder vertical Grinding mill

Composition of vertical grinding mill

CLUM vertical grinding mill is mainly composed of a bucket elevator, Hopper, main unit, a cyclone powder collector, dust cleaner, muffler, blower, soud-proof room and so on.

Working Principle of vertical grinding mill:

When the vertical grinding mill is at work, all the grinding rollers are rolling in the ring, and the materials are driven to the edge of the template by the centrifugal force and fall down into the grinding chambers where the materials are repeatedly pressed, crushed and ground by the rollers.

The high-pressure air blower constantly inhales air within the grinding mill and, in turn, the airflow with crushed materials are brought to the classifier whose high-speed impeller will screen the airflow: the unqualified particle size will fall and return to the mill for being reground while the qualified particle size mixed with air will go into the cyclone powder collector. Most of the qualified powders will fall and exit from the discharging valve at the bottom; a small proportion of the fine powders, with airflow, move to the dust cleaner, and clings to the surface of the filter bags. At the same time, the fine powders clinging to the surface fall down by the sudden vibration of the filter bags, which are caused by the instantly ejected high-pressure gas controlled by the pulse valve. The materials from the above two lots are sent by the conveyor at the bottom to get finished powders packed. In addition, filtered clean air will be emitted from the air outlet of the muffler in the end.

Getting more picture and info: Leaving a message on our website, or contact customer service to leave your mailbox.Thank you!

Application of vertical grinding mill

CLUM series vertical grinding Mill can be widely applied to process large-scale ultra fine powder, encompassing calcite, marble, limestone, barite, talcum, kaolin, dolomite, wollastonite, gypsum, feldspar, pyrophyllite and other non-metallic minerals.

Specification of ultrafine powder vertical Grinding mill

Composition of vertical grinding mill

CLUM vertical grinding mill is mainly composed of a bucket elevator, Hopper, main unit, a cyclone powder collector, dust cleaner, muffler, blower, soud-proof room and so on.

Working Principle of vertical grinding mill:

When the vertical grinding mill is at work, all the grinding rollers are rolling in the ring, and the materials are driven to the edge of the template by the centrifugal force and fall down into the grinding chambers where the materials are repeatedly pressed, crushed and ground by the rollers.

The high-pressure air blower constantly inhales air within the grinding mill and, in turn, the airflow with crushed materials are brought to the classifier whose high-speed impeller will screen the airflow: the unqualified particle size will fall and return to the mill for being reground while the qualified particle size mixed with air will go into the cyclone powder collector. Most of the qualified powders will fall and exit from the discharging valve at the bottom; a small proportion of the fine powders, with airflow, move to the dust cleaner, and clings to the surface of the filter bags. At the same time, the fine powders clinging to the surface fall down by the sudden vibration of the filter bags, which are caused by the instantly ejected high-pressure gas controlled by the pulse valve. The materials from the above two lots are sent by the conveyor at the bottom to get finished powders packed. In addition, filtered clean air will be emitted from the air outlet of the muffler in the end.

Getting more picture and info: Leaving a message on our website, or contact customer service to leave your mailbox.Thank you!