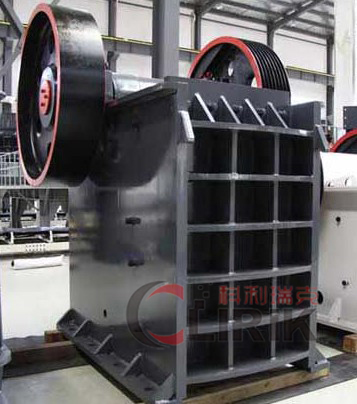

PE Jaw rusher

Jaw Crusher is one of the most popular stone-crushing equipments in the world, Jaw Crusher is ideally suitable for primary and secondary crushing. The highest anti-pressure strength of crushed material is 320MPA. Our design and production are of high position both at home and abroad.

Jaw Crusher can be used to crush material its compressive resistance not more than 320 MPA. It is widely used in various industries, such as mining, smelting, road and railway construction and chemical industry etc. PE Series is used to primary crushing; PEX series is used in secondary crushing and fine crushing.

Working Principle of PE Jaw Crusher

This crusher adopts the electric motor as the power. The eccentric shaft is revolved by an electric motor through v-belts. It causes the swing jaw following the preconcerted path to crush the feeding material. Thus the material will be crushed in the crushing chamber which is composed of the stationary jaw plate, swing jaw plate and the liner plate. The material is discharged from the lower part of machine that is what you want. Please carefully examine the fasteners, especially lubrication components and bolts, before the machine is started. Enough oil must be needed on each lubrication component. Fasten the loose bolts, clear the crushing cavity, and then start the machine. During the normal operation, even material feeding is important. Insufficient load or over load is not allowed. Moving jaw plate, fixed jaw plate, side guard plate and roof plate are wearing parts, and much attention should be paid to them.

Features of PE Jaw Crusher:

1. Crushing cavity is deep and there is no dead area, which improves feeding capacity and output;

2. High reduction ratio and uniform final product size;

3. Spacing piece type discharge-hole adjustment device is reliable and convenient;

4. Reliable and safe lubrication system, convenient replacement of parts and small work load of maintenance;

5. Simple structure, operational reliability and low operation cost;

6. Energy-saving : single machine can save energy by 15% to 30%; the system can save energy by over 30% to 60%;

7. Large adjustment range of discharge hole can meet the demands of different users;

8. Low noise and little dust;

9. Simple structure, convenient maintenance and use; stable performance, low operation cost; high reduction ratio.

10. The outlet employs pad-style adjustment devices, convenient and reliable, and increases the flexibility of the equipment.

Performance and parameter

| Type | PE150X250 | PE200X350 | PE250x400 | PEX250x400 |

| Opening size(mm) | 150X250 | 200x350 | 250x400 | 250x400 |

| Feeding size(mm) | ≤125 | ≤125 | ≤210 | ≤210 |

| Finished size(mm) | 10-40 | 15-40 | 20x60 | ≤12 |

| Power(KW) | 5.5-7.5 | 7.5-11 | 15-18.5 | 15-18.5 |

| Capacity(T/H) | 1-5 | 5-16 | 5-20 | 5-10 |