Benefit, applications and working principle of CLIRIK HGM se

Working principle of HGM ultrafine grinding mill

HGM series ultrafine grinding mill is on the bases of our company 10 years of manufacture experience. By plenitude review, investigation and try on 12 kinds of mills and horizontal crusher, by time after time investigation and experience we developed this high efficiency and low cost ultrafine grinding mill.

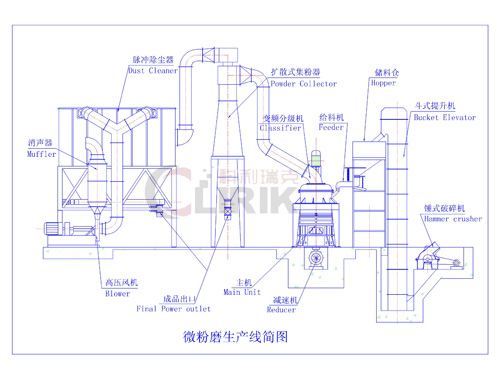

The whole system of the grinding mill consists of main unit, deceleration machine, classifier, blower, hammer crusher, bucket elevator, electro-magnetic vibrating feeder, pulse dust cleaner, piping device, cyclone collector device, classifier, high-pressure motor and muffler.

The main bearing and each dial are driven by electromotor of main equipment through reducer, when the HGM ultrafine grinding mill is at work. Then Dial drives numbers of rollers rolling and rotating in the ring by plunger.

Big materials are crushed into smaller particles by hammer crusher. Then they are sent to store house by elevator. The electro-magnetic vibrating feeder sends the materials evenly to the middle of the upper dial. Under the function of the eccentricity, the materials scatter to the side of the circle and fall into the ring to be pressed, crushed and milled into pieces by rollers. After the first crush, materials fall into the second and the third layer. The pumping of the high-pressure centrifugal blower put the outside air into the machine. The coarse powder will be brought into the classifier.

The rotating turbine in the collector makes the coarse particles fall back for regrinding. The fine particles will come into the cyclone collector with the airflow and discharged by the discharging valve on the bottom of the collector. They are the final products. The airflow with little dust will be discharged through blower and muffler after being purified by the cyclone collector.

Benefits of HGM ultrafine grinding mill

1. It can be applied in a wider range than airflow miller.

2. Compared with other micronizers, the rolling pressure upon materials form grinding roller with the help of high-pressure spring has increased 800-1200 kg.

3. Energy saving. In the case of the same output and fineness, its energy consumption is only one third of that of airflow miller.

3. Energy saving. In the case of the same output and fineness, its energy consumption is only one third of that of airflow miller.

4. Smaller investment and more benefit. In the case of the same output and fineness, the price is only one eighth of that of airflow miller.

5. It can be fed with large particles. The average diameter of discharged particles after being milled for once is below <5um.

6. The grinding setting adopts superposed multilevel sealing. So it has good sealing.

7. The dust cleaning meets the state dust discharging standard.

8. Convenient adjusting, more uniform particle size.

Application of HGM ultrafine grinding mill

HGM series ultrafine grinding mill is on the bases of our company’s production experience for more than 10 years. We absorb advantage from the same trade abroad and at home. We review, research and try on 12 kinds of mills and horizontal hammer crushers. And finally we developed this high-efficiency and low-cost ultrafine grinding mill by investigation and trial. This grinding mill is the equipment which produces fine powder and ultrafine powder. It is applicable to non-flammable and non-explosive materials with hardness less than Moh’s 6 scale, such as calcite, chalk, limestone, dolomite, kaolin, bentonite, talcum, talc, magnesite, illite, pyrophyllite, vermiculite, sepiolite, attapulgite, rectorite, diatomite, barite, gypsum, alum earth, graphite, fluorite, variscite, potash ore, floatstone and so on.

If you want to know more about clirik HGM ultrafine grinding mill, please click: http://www.grinding-equip.com