Table of Contents

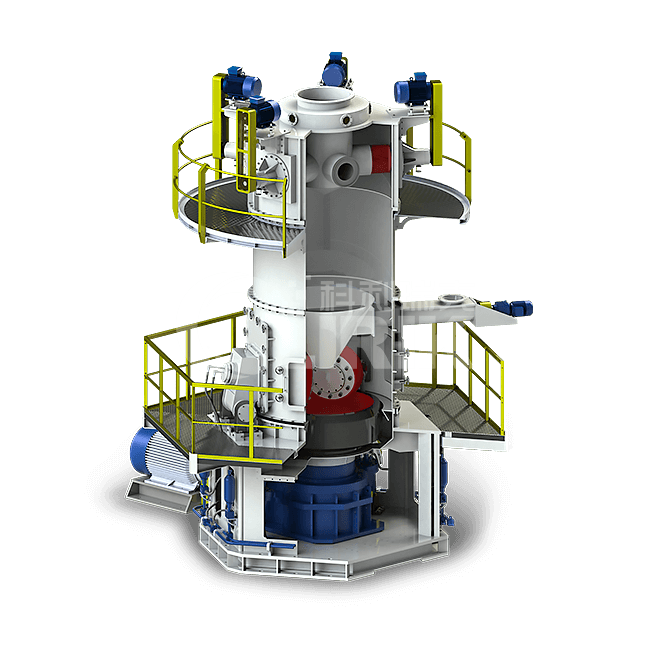

Name: 3000 mesh calcium carbonate powder grinding mill machine

Model: CLUM

Brand: Clirik

Application: 3000 mesh calcium carbonate powder grinding mill machine can be used in more than 1000 kinds of different types of stone materials 300-2500 mesh powder making, such as: calcium carbonate, calcite, gypsum, dolomite, feldsapr, carbon black and so on.

Capacity: According to your different powder fineness choose, the capacity is can be adjust between 0.2-45 t/h

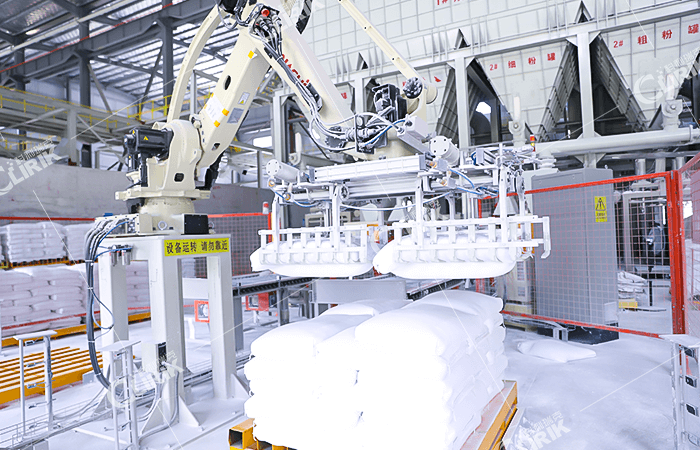

3000 mesh calcium carbonate powder grinding mill machine is a new type of milling equipment that includes grinding, grading, conveying, secondary powder selection, and finished product packaging. It is a large-capacity ultra-fine grinding and separation equipment.

1. The grinding wheel is driven by a motor through a reducer.

2. The calcium carbonate (or other ores material) is fed into the main machine of the 3000 mesh calcium carbonate powder grinding mill machine through the feed screw and falls into the center of the grinding disc.

3. Under the action of centrifugal force, the material spreads from the center of the grinding disc to the surroundings and is rolled into fine powder.

4. The powdery material continues to move to the edge of the grinding disc until it is taken away by the strong airflow from the air inlet and enters the high-efficiency classifier.

5. The qualified dust is collected by the integrator, and the unqualified dust is sent back for regrind.

• Good quality of finished products

• Advanced control system, saving labor force

• 3000 mesh calcium carboante powder grinding mill machine have CE, ISO9001

• Factory sell directly

• 30 years experience, professional

• Low noises, less dust, environmental protection

• Low wear rate, less metallic pollution, long service life

• Strong drying capacity: drying and grinding raw materials with a moisture content of up to 15%

| Main Configuration and Production | |||

| Model | CLUM1425 | CLUM1632 | CLUM1736 |

| Working Diameters(mm) | 1400 | 1600 | 1700 |

| Number of rollers(pieces) | 3 | 3 | 3 |

| Number of classifier(pieces) | 5 | 7 | 7 |

| Power of classifier(Kw) | 5X15 | 7X15 | 7X(15~18.5) |

| Main unit power (Kw) | 250 | 315 | 355 |

| Blower power(Kw) | 200 | 250 | 315 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

| Less than 2μm=34% output(t/h) |

11-14 | 13-17 | 15-19 |

| Less than 2μm=46% output(t/h) |

7-8 | 9-10 | 11-12 |

| Less than 2μm=60% output(t/h) |

3-4 | / | / |

| Material: based on calcite Particle size distribution: measured by micro laser diffraction particle size analyzer in British Malvern3000 instruments |

|||

Shanghai Clirik Machinery Co., Ltd, located in Pudong New Area of Shanghai, China, is a large professional manufacturer with import & export rights specializing in research, manufacture and sales of crushing machinery, mining equipment, and grinding machines.

Whether you need a for micro powder grinding equipment, ultrafine grinding equipment, stone grinding equipment, mineral grinding machine, hammer crushers, jaw crushers and associated accessories, we have the perfect solution for your unique requirements.

Pre-sale

Free to help customers in equipment selection and scheme design.

You are always welcomed to visit Clirik! Visit our prototype and showroom.

On-sale

Strictly implement quality standards, and guarantee the quality of products shipped.

Strictly implement the standard process of preparation and delivery, timely and accurate stock preparation, and rapid delivery.

After-sale

Overseas professional installation team provides technical guidance for equipment installation and commissioning.

Train the start-up process, teardown method, common problems and maintenance service.

Professional after-sales service team, 24 hours response to customer needs.

1. What is the production process of 3000 mesh calcium carbonate powder grinding mill?

A. Crushing system: raw material silo→feeder→jaw crusher→belt conveyor→de-ironing separator→hammer crusher→elevator→dust

collector→surge bin.

B. Grinding system: quantitative belt scale→elevator→spiral conveyor→de-ironing separator→ultrafine vertical mill→pulse dust

collector→fan→air door.

C. Conveying system: elevator or pneumatic conveyor.

D. Auxiliary system: agent adding system, compressed air system, water cooling system.

2. Who are we?

Shanghai Clirik Machinery Co., Ltd is specializing in research, manufacture and sales of all kinds of grinding mill. We have been devoted to grinding fields for more than 30 years.

3. What payment methods can we accept?

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union